Designing the Ultimate Fibre Optic Splicing Van: 7 Must-Have Features for Productivity and Comfort

May 5, 2025

In today’s world of rapid connectivity, the demand for reliable fibre optic infrastructure has never been greater. Behind every seamless internet connection lies the critical work of fibre optic technicians—often performed in the field, in all weather conditions. That’s where a fibre optic splicing van becomes invaluable.

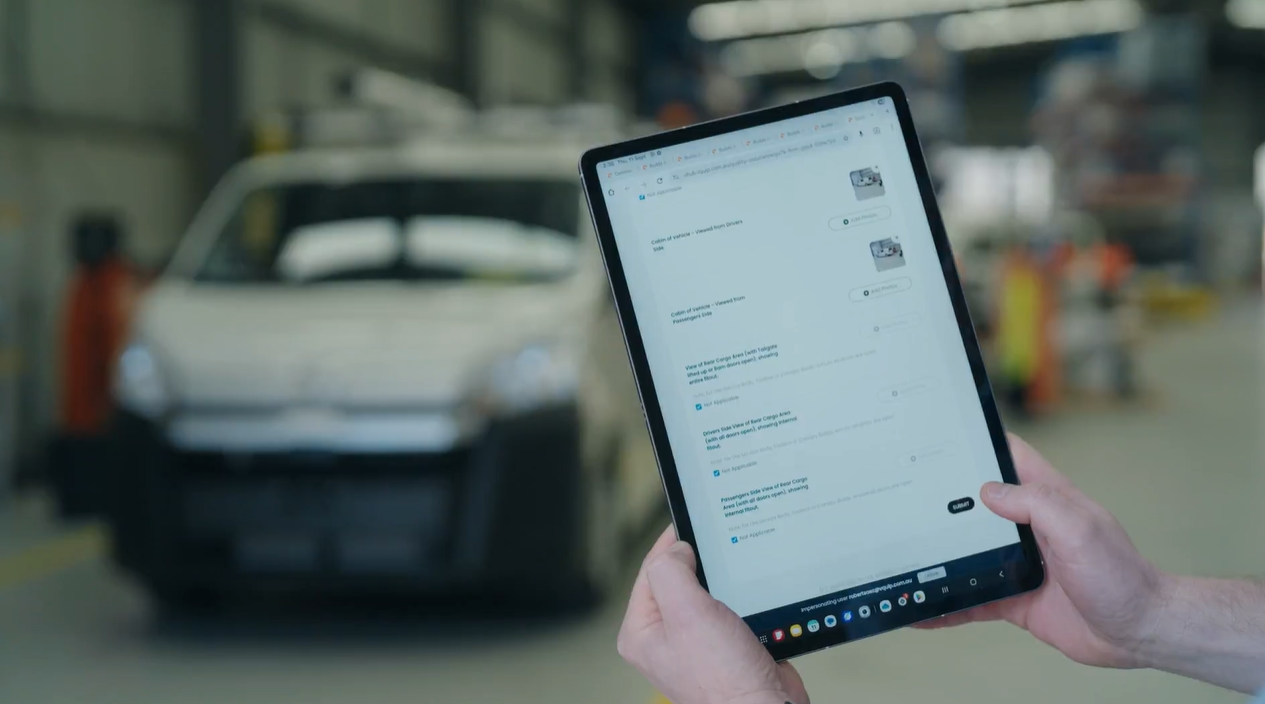

A well-designed splicing van isn’t just a vehicle—it’s a mobile, self-contained workshop that ensures technicians can deliver high-quality, precise splicing work anywhere, anytime. But what makes a splicing van truly functional, comfortable, and efficient? Below, we explore essential tips for designing the ultimate splicing van, including the increasingly popular feature: a splicing hatch in the rear doors.

-

Prioritise a Clean, Dust-Free Work Environment

Fibre optic splicing requires extreme precision. Dust, moisture, and temperature fluctuations can compromise the integrity of a splice. Therefore, your van should be designed as a clean and controlled environment.

✅ Consider installing sealed wall and ceiling panels that resist dust build-up.

✅ Include a rubber or vinyl flooring that’s easy to clean and anti-static.

This attention to cleanliness doesn’t just protect the fibre—it extends the lifespan of your sensitive splicing equipment.

-

Plan an Ergonomic Workstation Layout

Technicians often spend hours splicing, so comfort and efficiency are key. Your van layout should enable technicians to work comfortably while maximising space.

Some design considerations include:

- A fixed workbench at standing or sitting height for the splicing machine.

- A fold-out desk or secondary work surface for documentation, testing, and laptop use.

- Accessible power outlets at bench height for easy plugging in of tools.

- Ample headroom so technicians can stand without discomfort.

Don’t underestimate ergonomics. A poorly planned workspace can lead to fatigue, mistakes, and lower productivity.

-

Incorporate Sufficient Power and Backup Supply

Fibre splicing equipment relies on stable electricity. Your van should be equipped with a reliable power system that caters for both standard operations and emergency backup.

Key recommendations:

✅ A 240V power and inverter system to run sensitive electronic devices.

✅ Deep-cycle auxiliary batteries to support equipment without draining the vehicle battery.

Ensure all electrical components comply with safety standards and have sufficient surge protection.

-

Add a Rear Splicing Hatch for Cable Management

One innovative feature increasingly used in splicing van designs is a splicing hatch installed in the rear doors. This hatch allows technicians to feed fibre optic cables directly into the van for splicing, without fully opening the doors—a clever way to maintain the clean environment inside.

Why is this important?

- Reduces dust and contaminants entering the van while cables are brought in.

- Prevents exposure to wind or rain during splicing work.

- Saves time on setup since cables can remain outside on reels.

When adding a splicing hatch:

✅ Ensure the hatch is weather-sealed and lockable for security.

✅ Position the hatch at a height that aligns with your interior cable handling system.

This feature can dramatically improve efficiency and cleanliness—especially valuable when working on roadside or rural projects.

-

Invest in Effective Climate Control

Temperature and humidity are critical factors in fibre optic splicing. Too hot, too cold, or too humid can impact splice quality and technician comfort. Therefore, your van needs robust climate control.

Consider installing:

- A rooftop air conditioner unit for year-round temperature regulation.

- Insulated walls and ceilings to maintain interior temperature more efficiently.

Maintaining a stable interior environment keeps both technicians and equipment in optimal working condition.

-

Maximise Storage and Organisation

A cluttered van isn’t just inconvenient—it’s a hazard. Every tool, spare part, and consumable needs a designated place to keep the workspace clear and professional.

Storage tips:

✅ Install modular shelving around the van (along with a splicing workbench) for storing splicing consumables, tools, and cleaning supplies.

✅ Use storage and parts bins for easy access to small parts like splice protectors and connectors.

✅ Include a secure storage area for expensive testing equipment like OTDRs and power meters.

Also consider rack-mounted storage for items like patch panels or test cables that need to stay untangled and damage-free.

-

Don’t Forget Practical Extras

The little things make a big difference in a splicing van. Here are a few additional features to consider:

- LED lighting with dimmable control to reduce eye strain while maintaining visibility.

- External floodlights for illuminating work areas outside the van.

- A fire extinguisher and first aid kit within easy reach for safety compliance.

Each of these additions contributes to a safer, smarter, and more functional mobile workshop.

Final Thoughts: Build for Efficiency, Comfort, and Quality

Designing a fibre optic splicing van isn’t just about fitting out a vehicle—it’s about creating an environment where technicians can perform high-precision work under any conditions. Every design choice should balance efficiency, cleanliness, safety, and technician comfort.

From a dust-free interior to a thoughtfully integrated splicing hatch in the rear doors, each element plays a role in achieving high-quality outcomes in the field. Whether you’re an independent contractor or managing a fleet for a telecommunications provider, investing in a well-designed splicing van will pay dividends in productivity, reliability, and job satisfaction.

Ready to start building your ultimate splicing van? Consider consulting with a professional fitout company that understands the unique requirements of fibre optic work to bring your vision to life.

Interested in learning more about specialist vehicle fitouts? Contact us for advice or a custom quote tailored to your team’s needs.