Flat Plate vs Checker Plate Toolboxes: Which Is Right for Your Fleet?

Jun 18, 2025

When it comes to ute toolboxes, the material you choose isn’t just about looks—it’s about durability, safety, usability, and long-term brand image. One of the most common decisions fleet managers and tradespeople face is choosing between flat plate and checker plate aluminium toolboxes.

Each has its strengths, but the right choice comes down to how your vehicles are used and what image you want to project. In this article, we explore the pros and cons of each option to help you make a more informed decision for your fleet.

What Is a Checker Plate Toolbox?

Checker plate (also known as tread plate or diamond plate) is an aluminium sheet with a raised pattern of diamonds or lines. It’s commonly used in trades due to its robust and non-slip properties.

✅ Benefits of Checker Plate:

- Durability: The textured pattern adds strength, making it ideal for demanding worksites.

- Scratch and Dent Resistant: The raised surface hides marks, keeping toolboxes looking better for longer.

- Slip Resistance: Provides grip when used as a platform or step.

❌ Considerations:

- Harder to Clean: The grooves can collect dirt, making cleaning more involved.

- Slightly Heavier: The extra material in the pattern can increase weight marginally.

- Limited Signwriting Capability: The uneven surface makes vinyl wraps and decals difficult to apply cleanly.

- Industrial Aesthetic: May not suit customer-facing environments or vehicles representing your brand.

What Is a Flat Plate Toolbox?

Flat plate aluminium has a smooth, even surface and is growing in popularity—particularly among fleet operators who want their vehicles to reflect a clean, professional image.

✅ Benefits of Flat Plate:

- Modern Appearance: Sleek and streamlined, great for professional fleet presentation.

- Easy to Clean: Flat surfaces can be wiped down quickly and maintain a polished look.

- Signwriting Friendly: Ideal for branding, decals, safety signage or full vehicle wraps.

- Slight Weight Advantage: Without textured ridges, it can be marginally lighter in some builds.

❌ Considerations:

- Scratch Visibility: Surface imperfections are more noticeable on flat aluminium.

- Less Rugged: May show dents more readily in high-impact environments.

🖊️ Can You Signwrite Checker Plate?

One of the biggest practical differences between flat and checker plate toolboxes is branding capability.

Checker plate toolboxes are not well-suited to signwriting. The raised diamond pattern prevents vinyl decals from adhering smoothly, leading to peeling, bubbling, or uneven finishes. If your fleet includes vehicles that need clear, consistent company branding or safety labelling, checker plate may not meet those requirements.

In contrast, flat plate toolboxes are ideal for signwriting, allowing for:

- Company logos

- Reflective safety stickers

- Fleet numbering

- Full or partial vinyl wraps

If visual consistency and brand presence are priorities for your business, flat plate is the better choice.

Quick Comparison: Flat Plate vs Checker Plate

| Factor | Checker Plate | Flat Plate |

| Appearance | Rugged, industrial | Sleek, modern |

| Durability | High impact resistance | Durable, but marks more visible |

| Weight | Slightly heavier | Slightly lighter |

| Ease of Cleaning | Harder to clean | Easy to wipe down |

| Scratch Resistance | Hides marks well | Shows scratches more clearly |

| Signwriting Surface | Not suitable | Ideal for branding and signage |

VQuip’s Recommendation

At VQuip, we offer both flat plate and checker plate toolbox options to suit different fleet needs. If you’re operating in harsh environments like construction or remote field service, checker plate offers unbeatable durability.

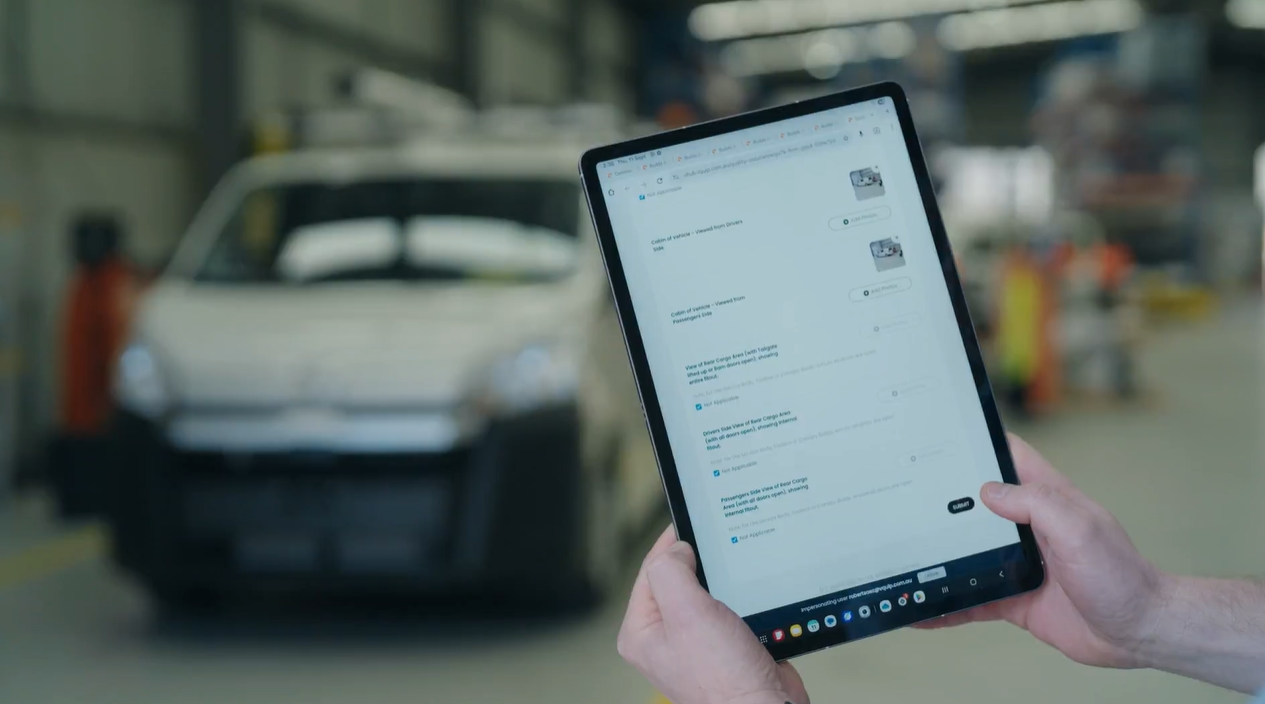

However, if your fleet operates in metropolitan areas, makes customer site visits, or needs to carry branding and safety signage, flat plate toolboxes provide a clean and professional look that supports brand visibility.

📞 Need Help Choosing? Let’s Talk.

Still unsure which is right for your fleet? Our team can help you choose the best option based on your vehicles, industry, and operational requirements. Whether you’re outfitting a single ute or rolling out a national fleet, we’re here to help you get it right the first time.

Get in touch with the VQuip team today to discuss the best toolbox solution for your business.