How to Reduce the Risk of Injury with a Well-Designed Van Fitout

Jun 15, 2025

Your van layout could be putting your team at risk — here’s how smart design can prevent it.

When businesses talk about improving safety, the focus is often on high-visibility PPE, vehicle maintenance, or safe driving practices. But there’s one area that’s just as important — and often overlooked: the layout and setup of the work vehicle itself.

For tradies, technicians, and mobile workers, the van is more than just transport — it’s a mobile workshop. And like any workspace, poor design leads to inefficiency, frustration, and worst of all, injury.

In fact, many common workplace injuries — from strains and sprains to slips and impacts — can be directly linked to poor vehicle fitouts. Unsecured equipment, difficult-to-reach tools, and cluttered spaces are just a few of the hazards your team might be facing every day.

So how can you design a van fitout that actually reduces risk and promotes a safer, more productive workday?

Let’s break it down.

1. Reduce Manual Handling Through Smart Layouts

Manual handling is one of the biggest contributors to workplace injury in mobile workforces. Constant bending, twisting, and overreaching puts unnecessary strain on the body — especially when repeated multiple times a day.

Common issues:

-

Frequently used tools stored on the floor or overhead

-

Heavy items with no slide-out access

-

Lack of side access to internal shelves

Fitout solution:

A smart fitout places high-use tools and parts at waist height and within arm’s reach. VQuip’s drawer systems, for example, allow workers to access gear without stepping into the van or awkwardly leaning. With full-extension slides, you don’t need to dig through shelves — everything is visible and easy to grab.

2. Secure Tools and Equipment to Prevent Impact Injuries

When gear isn’t secured properly, it becomes a major hazard during transit. A sudden stop can turn a cordless drill or tool bag into a projectile — risking serious injury to the driver or passenger.

Common issues:

-

Loose items left on floors or open shelving

-

Makeshift tie-downs that fail under load

-

Heavy items stacked unsafely

Fitout solution:

VQuip fitouts can include fully enclosed shelving end panels, adjustable lashing points, lockable drawers, and custom mounts to keep equipment in place. We also use rated cargo barriers to separate the cargo area from the cabin — a simple addition that should be a non-negotiable one, and can prevent major injuries in the event of a crash or abrupt stop.

3. Improve Visibility and Reduce Trip Hazards

Dimly lit, cluttered spaces make injuries more likely — especially in early mornings or poor weather. When you can’t clearly see where you’re stepping or what you’re reaching for, it’s easy to trip, bump, or slip.

Common issues:

-

Poor lighting inside the van

-

Sharp edges or exposed metal

-

No clear walking or working space

Fitout solution:

Integrated LED lighting, wall panelling, and anti-slip flooring all contribute to safer working conditions. We also design fitouts to maximise open floor space and eliminate unnecessary clutter. Better visibility means fewer accidents — and a more efficient workflow.

4. Tailor the Fitout to the Job to Avoid Unsafe Workarounds

One of the biggest safety risks comes from using a fitout that doesn’t match how the vehicle is actually used. Workers are forced into risky workarounds: climbing into the van, storing gear loosely, or modifying setups on the fly.

Common issues:

-

“One-size-fits-all” storage that doesn’t suit the task

-

Lack of dedicated storage for sharp, hot, or hazardous items

-

No accommodation for job-specific tools or materials

Fitout solution:

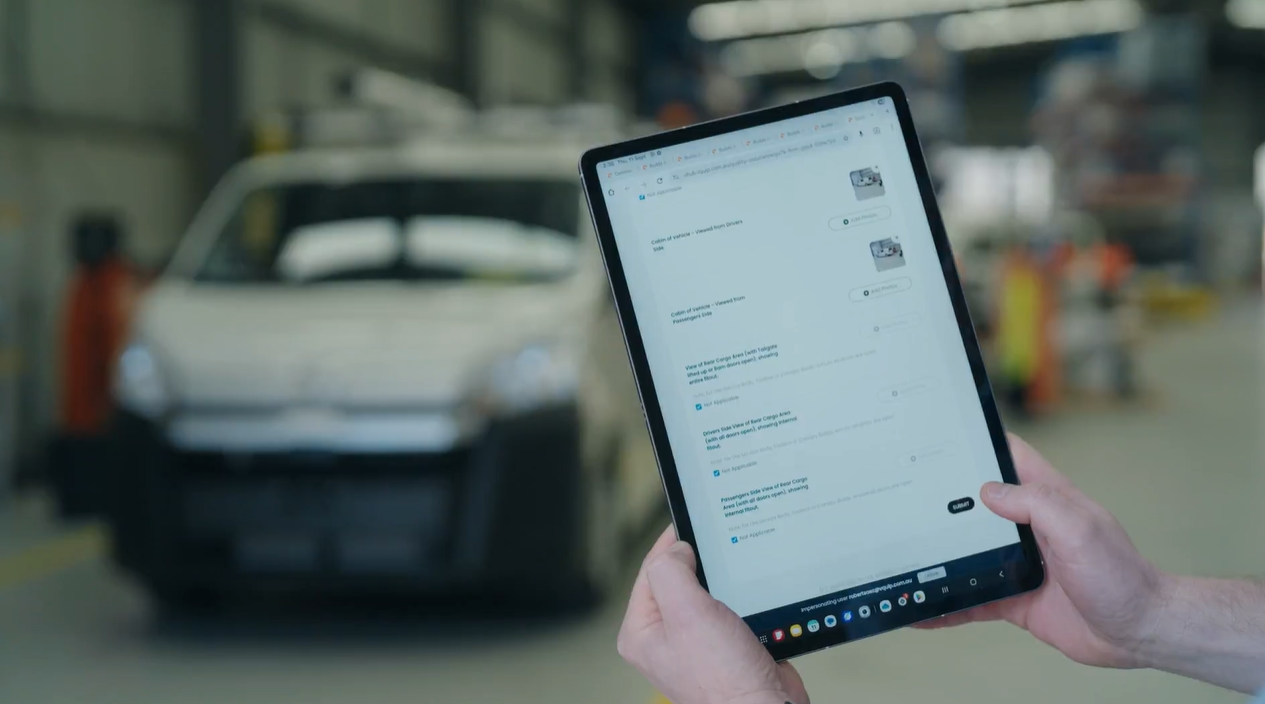

At VQuip, we collaborate with your team to understand your trade, tools, and typical workflow. That means every fitout is tailored — whether it’s adding lockable gas bottle boxes, tool-specific racks, or dual access systems. When the setup fits the task, the risk of injury drops dramatically.

5. Make Loading and Unloading Safer

Every time a worker climbs in and out of the van, there’s a risk — especially when lifting awkward or heavy gear. And let’s face it: doing that dozens of times per day adds up fast.

Common issues:

-

Steep access to rear cargo areas

-

Lifting heavy gear above shoulder height

-

No assistive equipment for bulky items

Fitout solution:

We use ergonomic design principles to reduce these risks. That includes rear access steps with anti-slip tread, gas-assisted lifts for roof racks, and pull-out trays for large items. By making loading easier and safer, you reduce fatigue and prevent cumulative stress injuries.

6. Keep Safety Front of Mind with Every Build

Fitout safety isn’t just about the hardware — it’s about the mindset. A good safety culture starts with the tools and equipment your team uses every day. If your van promotes safe, efficient work, your team is more likely to follow suit.

VQuip’s approach:

We take safety seriously at every step — from initial consultation through to install. We understand that a fitout isn’t just storage — it’s a key part of your team’s daily safety and performance.

A Safer Fleet is a Smarter Investment

Investing in safer fitouts isn’t just about protecting your people — it also reduces lost time, compensation claims, and unplanned downtime. When your team is confident in their gear and their setup, they can get the job done faster, better, and more safely.

At VQuip, we’ve helped hundreds of companies across Australia create van and ute fitouts that reduce risk and improve day-to-day operations. Whether you’re fitting out a single vehicle or rolling out a national fleet, we’ll work with you to build something that works — and keeps your people safe.