How to Spec a Fleet Fitout: A Step-by-Step Guide for Fleet Managers

Jan 19, 2026

Specifying a fleet fitout for 100+ vehicles is one of the most critical decisions you’ll make as a fleet manager. Get it right, and you’ll deliver efficiency gains, reduce downtime, and make your team’s job easier. Get it wrong, and you’re looking at cost overruns, compliance issues, and ongoing operational headaches.

Whether you’re rolling out a new fleet or standardizing existing vehicles, this guide will walk you through the essential steps to spec a fitout that delivers results.

Step 1: Start With the Work, Not the Vehicle

The biggest mistake fleet managers make is starting with the vehicle platform before understanding the actual work requirements.

Ask yourself:

- What tasks do our technicians perform daily?

- What tools and equipment must be accessible on every job?

- How much material do they carry on average?

- What are the most common workflow bottlenecks?

Action: Spend time with your field teams. Shadow a technician for a day. Watch how they access tools, move equipment, and organize their workspace. The insights you gain will be worth more than any supplier brochure.

Step 2: Define Your Non-Negotiables

Before you engage with suppliers, establish your absolute requirements. These typically fall into three categories:

Compliance Requirements

- Weight and load ratings (GVM/GCM compliance)

- WHS obligations for safe tool storage and access

- Industry certifications (e.g., government tender requirements)

- ADR compliance for vehicle modifications

- Insurance requirements

Operational Requirements

- Tool security (theft prevention)

- Weather protection for equipment

- Accessibility (can technicians reach everything safely?)

- Durability for harsh environments

- Serviceability across your operating regions

Business Requirements

- Brand standards and vehicle livery

- ESG commitments (materials, suppliers, end-of-life considerations)

- Budget parameters

- Delivery timelines

- Standardisation across fleet

Pro Tip: Document these in a requirements matrix. This becomes your evaluation scorecard when comparing suppliers and solutions.

Step 3: Involve the Right Stakeholders Early

Fleet fitout specifications shouldn’t be created in isolation. You need input from:

- Field technicians – They know what works (and what doesn’t) in daily operations

- Operations managers – They understand workflow efficiency and productivity metrics

- Finance – They can model TCO and ROI scenarios

- Procurement – They know contract structures and supplier performance

- WHS/Compliance – They ensure safety and regulatory requirements are met

- Leasing partners – If you’re working with a leasing company, involve them early to align on residual values and lease structures

Getting alignment upfront prevents costly specification changes mid-project.

Step 4: Standardise Where Possible, Customize Where Necessary

Standardisation drives efficiency and cost savings. Every custom variation adds complexity, lead time, and expense.

Standardise:

- Core storage configurations (drawers, shelving, toolboxes)

- Materials and finishes

- Mounting systems

- Electrical setups (inverters, 12V outlets, lighting)

Customise:

- Industry-specific requirements (HVAC vs. plumbing vs. electrical)

- Regional variations (urban vs. remote operations)

- Specialist equipment mounts

- Unique compliance needs

Example: A mechanical services fleet might standardise on drawer configurations and toolbox placement, but customise compartment dividers for HVAC technicians vs. plumbers.

Step 5: Material Selection Matters More Than You Think

Not all fitout materials are created equal. Your choice directly impacts durability, weight, cost, and vehicle performance.

Common Materials:

Marine-grade plywood

- Pros: Weather-resistant, strong, proven performance

- Cons: Heavier than alternatives

- Best for: Long-term durability in harsh conditions

Aluminum

- Pros: Lightweight, corrosion-resistant

- Cons: Can dent, higher cost

- Best for: Weight-sensitive applications, coastal environments

Powder-coated steel

- Pros: Extremely durable, cost-effective

- Cons: Weight, potential rust if coating damaged

- Best for: Heavy-duty applications, high-wear environments

Plastic/composite

- Pros: Lightweight, won’t rust

- Cons: Can crack, less robust

- Best for: Light-duty applications

Key Consideration: Don’t just look at upfront cost. A lighter fitout might allow you to carry more payload, while a heavier but more durable fitout might reduce replacement costs over the lease term.

Step 6: Plan for Weight and Load Distribution

This is where many specifications fail compliance—and where fleet managers face genuine liability risk.

Critical checks:

- Calculate total fitout weight (including all accessories, tools, and typical payload)

- Ensure you’re within GVM (Gross Vehicle Mass) limits

- Consider GCM (Gross Combination Mass) if towing

- Account for weight distribution (front/rear axle loads)

- Plan for worst-case scenarios (full tool load + materials + equipment)

Pro Tip: Request detailed weight specifications from your fitout provider. If they can’t provide them, that’s a red flag. A quality supplier will engineer solutions that keep you compliant.

Step 7: Specify Quality Control and Documentation

Your specification should define what quality looks like and how it’s verified.

Include:

- Material standards and certifications

- Build quality requirements (welds, fixings, finishes)

- Pre-delivery inspection process

- QC reporting (photos, measurements, compliance verification)

- Warranty terms and what’s covered

- As-built documentation

Why this matters: Clear QC specifications prevent disputes, ensure consistency across 100+ vehicles, and give you evidence that standards were met.

Step 8: Build in Project Visibility

One of the biggest frustrations for fleet managers is the “black hole” period between order and delivery.

Specify:

- Project milestones and reporting cadence

- Communication protocols (who contacts whom, when, and how)

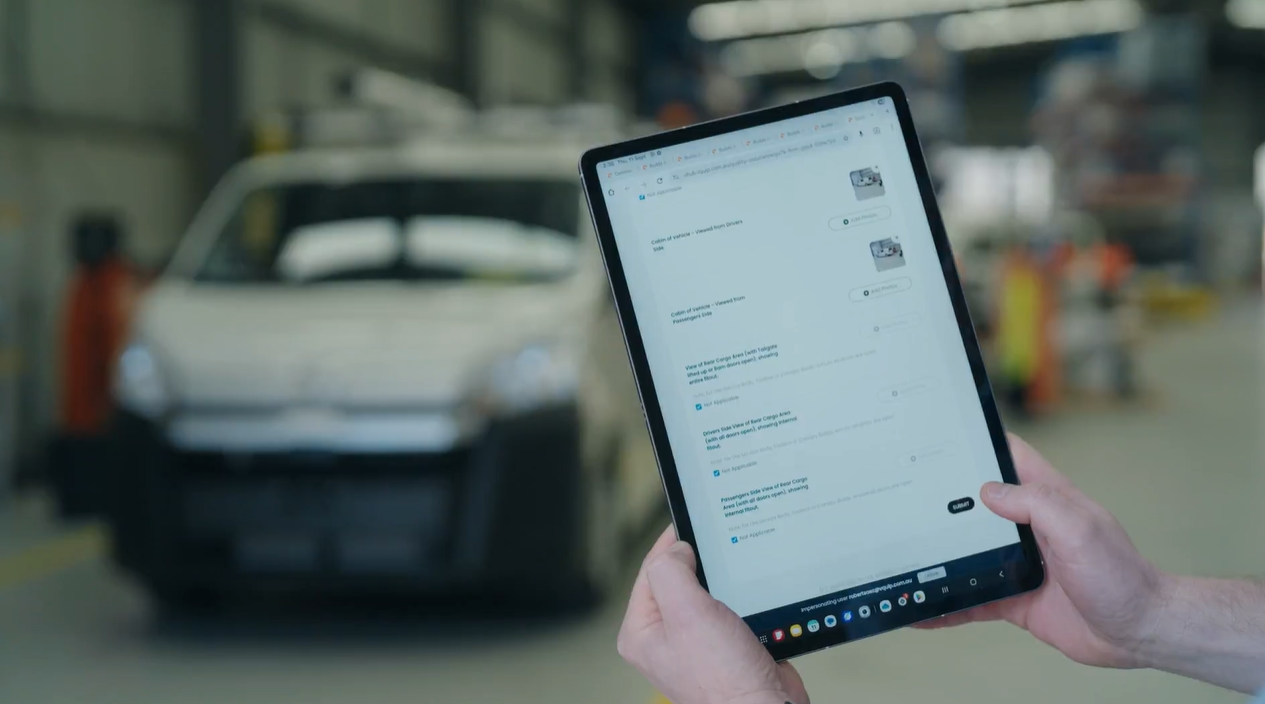

- Access to build progress (photos, tracking systems like VHub)

- Issue escalation process

- Delivery scheduling and logistics coordination

Modern Expectation: In 2026, fleet managers should have real-time visibility into their fitout projects. If your supplier can’t offer this, they’re behind the curve.

Step 9: Think About the Full Lifecycle

Your specification shouldn’t just cover the initial build. Consider:

During the Lease:

- Serviceability (can standard components be replaced easily?)

- Parts availability

- Repair processes if damaged

- Modification flexibility if business needs change

At Lease End:

- Removal requirements

- Vehicle reinstatement costs

- Fitout transferability to new vehicles

- Remarketing impact on residual values

Smart Move: Specify modular components where possible. This gives you flexibility to adapt as business needs evolve without replacing entire fitouts.

Step 10: Define Success Metrics

How will you know if your fitout specification was successful?

Measure:

- On-time delivery rate

- Quality defect rate

- Technician satisfaction scores

- Downtime incidents related to fitouts

- Warranty claims

- Budget variance

- Compliance audit results

- Productivity improvements (jobs per day, tool access time)

Tip: Establish baseline metrics before rollout, then track improvements. This data becomes invaluable for future specifications and business cases.

Common Specification Mistakes to Avoid

- Over-specifying: Adding features “just in case” drives up cost and lead times. Stick to genuine requirements.

- Under-specifying: Vague specifications lead to mismatched expectations and disputes. Be specific.

- Ignoring consultation: Field teams have the answers. Not asking them is leaving money on the table.

- Forgetting about standardisation: Every variation multiplies your management complexity.

- Choosing price over value: The cheapest fitout rarely delivers the lowest total cost of ownership.

- Not planning for scale: If you’re fitting 100+ vehicles, ensure your supplier has the capacity and systems to deliver consistently.

The Right Partner Makes All the Difference

Even the best specification needs the right supplier to execute it. Look for partners who:

- Have proven experience with large fleet rollouts

- Offer transparent processes and project visibility

- Provide detailed QC documentation

- Communicate proactively, not just when asked

- Can demonstrate consistent lead times and quality

- Act as an extension of your team, not just a vendor

A quality fitout supplier will challenge your assumptions, offer alternatives you haven’t considered, and help you avoid expensive mistakes.

Ready to Spec Your Fleet Fitout?

Specifying fleet fitouts doesn’t have to be overwhelming. With a structured approach, stakeholder input, and the right partner, you can deliver fitouts that improve efficiency, meet compliance requirements, and make your team’s job easier.

At VQuip, we work with fleet managers every day to translate business requirements into practical, reliable fitout solutions. Whether you’re managing 100 or 1,000 vehicles, we’re here to make your job easier.

Need help getting started? Contact our team for a no-obligation consultation about your fleet fitout requirements. We’ll help you ask the right questions and avoid the common pitfalls.