Smart Storage: How RFID and Tracking Improve Fleet Inventory

Aug 26, 2025

For many fleets, keeping track of tools, parts, and consumables is one of the most frustrating day-to-day challenges. A van may start the week stocked with everything a technician needs, but by Friday, items are missing, duplicated, or scattered across multiple vehicles. The result? Lost time, wasted money, and frustrated teams.

This is where RFID (Radio Frequency Identification) and smart tracking systems are starting to transform the way fleets manage inventory inside their vehicles. By combining clever van fitout design with digital tracking, fleet managers can move beyond the guesswork of manual stocktakes and unlock a new level of efficiency.

What Is RFID and How Does It Work?

RFID uses small tags and radio waves to identify and track items automatically. Unlike barcodes, RFID tags don’t need to be scanned one by one—they can be read instantly, even if they’re inside a toolbox or behind a panel.

Each tag contains a unique ID linked to an item, whether that’s a spare part, a tool, or a consumable like fasteners or PPE. When paired with RFID readers inside vans or at depots, fleet managers can see what’s in each vehicle, what’s been removed, and when items need replenishing.

The Benefits of Smart Inventory Tracking

- No More “Stock Guesswork”

Technicians often carry more stock than they need, just in case. With RFID, real-time visibility means managers can issue vehicles with the right stock levels, reducing duplication and lowering costs.

- Faster Job Readiness

Nothing kills productivity like arriving on site only to discover a missing part. With RFID-equipped fitouts, managers can set alerts when essential items are missing from a van before it leaves the depot.

- Improved Asset Security

High-value tools are often misplaced or go missing. RFID provides an audit trail, so managers know when and where equipment was last seen, reducing loss and theft.

- Simplified Compliance and Reporting

For industries where safety gear and equipment must be tracked, RFID takes the manual burden out of compliance. Managers can instantly generate reports showing proof of equipment availability and maintenance history.

- Seamless Restocking

When linked with procurement or warehouse systems, RFID can trigger automatic restock requests. That means fewer calls from technicians chasing parts, and more uptime for vehicles.

Practical Applications in Fleet Fitouts

At VQuip, we see RFID as an extension of a well-designed fitout—not a replacement. Smart storage starts with:

- Custom shelving and bins designed to house tagged items consistently.

- RFID readers installed at strategic points inside the van.

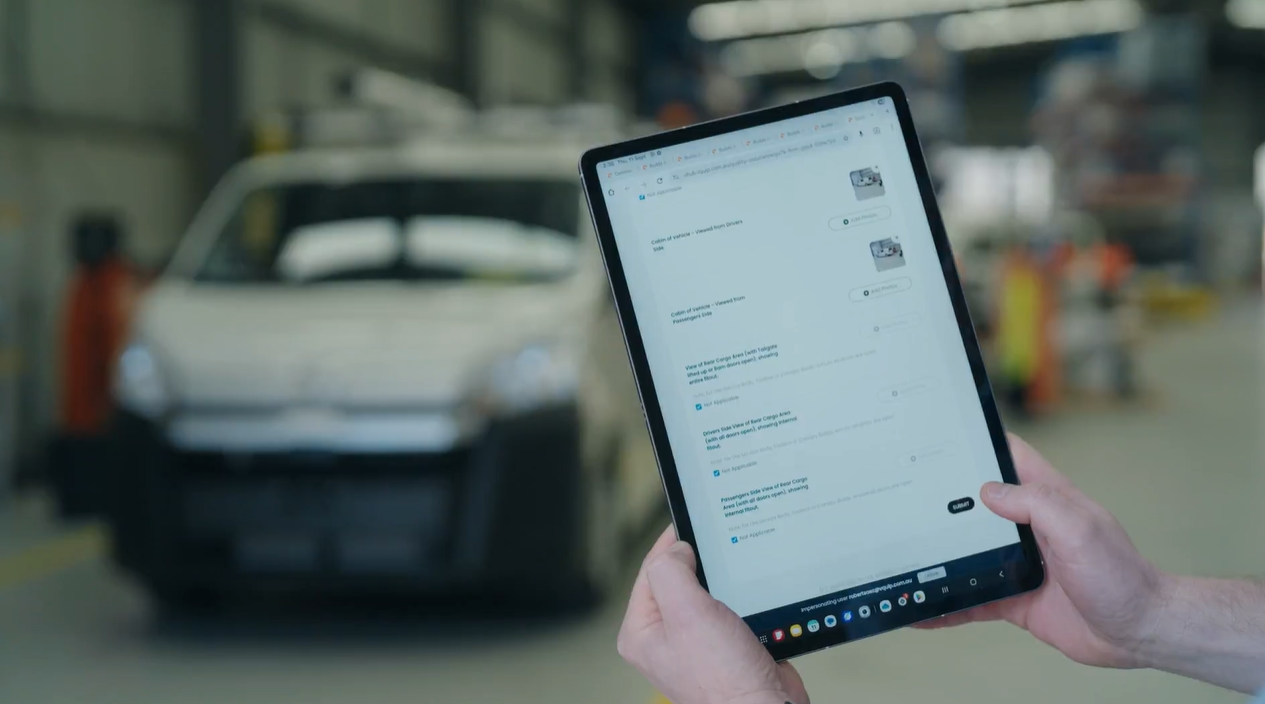

- Software integration that connects fleet managers to dashboards and mobile alerts.

Imagine a technician starting their day. As they load their vehicle, the system checks each tagged item and confirms everything is ready. At the end of the week, managers can see what’s been used, where gaps are, and even spot patterns—like overuse of certain consumables in one region compared to another.

Looking Ahead: AI Meets RFID

As RFID integrates with AI and predictive analytics, fleets will go beyond tracking what’s on hand—they’ll start forecasting what’s needed. For example:

- Predictive restocking based on historical usage.

- Automated alerts when equipment is nearing end-of-life.

- Insights into tool utilisation across multiple depots.

This future isn’t far away, and the fleets who embrace smart storage early will be the ones who benefit most.

Final Word

Fleet vehicles are no longer just a means of transport—they’re mobile warehouses and workshops. By combining intelligent fitouts with RFID and tracking technology, businesses can improve efficiency, reduce costs, and give their teams the confidence that every vehicle is fully stocked and job-ready.

At VQuip, we believe the next generation of fleet fitouts won’t just be about physical storage—it will be about data-driven storage. And the fleets that adopt smart systems now will be the ones setting the standard in the years ahead.