Standardising Fleet Fitouts Without Losing Role-Specific Functionality

Dec 23, 2025

How large fleets balance consistency with trade-specific needs

As fleets grow, complexity grows with them.

What starts as a handful of vehicles fitted out one by one can quickly become a patchwork of layouts, storage systems, accessories, and exceptions. Different depots, different trades, different preferences. Over time, this lack of consistency creates real operational pain.

Large fleets know they need standardisation. But many hesitate, worried that a standard fitout will force technicians into a one-size-fits-all solution that does not actually support how they work.

The good news is this: standardisation and role-specific functionality are not opposites. When done correctly, they reinforce each other.

Here is how well-run fleets strike that balance.

Why Standardisation Matters for Large Fleets

Standardisation is not about uniformity for its own sake. It is about control, efficiency, and predictability at scale.

For fleet managers, consistent fitouts deliver clear benefits:

- Faster vehicle rollouts and replacements

- Reduced design and approval cycles

- Easier maintenance and repairs

- More predictable costs

- Simplified training and onboarding

- Improved safety and compliance

When every vehicle is different, every decision becomes a custom decision. That drives cost, delays, and risk.

Standardisation creates a baseline that the entire organisation can rely on.

Where Standardisation Often Goes Wrong

Problems arise when standardisation is interpreted too narrowly.

Some fleets attempt to lock down a single layout across all vehicles, regardless of role. The result is predictable:

- Technicians modify vehicles themselves

- Storage gets misused or overloaded

- Productivity drops

- Safety risks increase

- Morale suffers

This is not a failure of standardisation. It is a failure of design logic.

Effective standardisation does not start with a fixed layout. It starts with understanding how different roles actually use their vehicles.

Step One: Define Core Fleet Requirements

The most successful fleets begin by identifying what should be common across every vehicle.

These are the elements that benefit from consistency, regardless of trade:

- Vehicle platform and size range

- Shelving system architecture

- Fixing methods and load ratings

- Electrical standards

- Safety equipment

- Labelling and signage

- Quality and compliance requirements

This forms the core fitout platform.

By standardising these foundations, fleets create stability without dictating every detail of how space is used.

Step Two: Group Roles by Functional Similarity

Rather than designing fitouts trade by trade, leading fleets group roles by how work is performed.

For example:

- Field service technicians

- Electrical and data technicians

- Maintenance and facilities teams

- Installation and commissioning crews

- Multi-trade response teams

Each group shares common behaviours, even if job titles differ. This allows fleets to design role-based templates rather than dozens of bespoke layouts.

A facilities technician and an HVAC technician may need different tools, but their storage, access, and workflow requirements often overlap far more than expected.

Step Three: Standardise the Framework, Not the Contents

A key principle in scalable fitout design is this:

Standardise the structure. Customise the configuration.

This means keeping the same shelving system, mounting points, and layout zones, while allowing flexibility in how those zones are populated.

For example:

- The same shelving frame across all vehicles

- The same drawer sizes

- The same locations for safety equipment and power

- Different combinations of drawers, bins, and open bays depending on role

From the outside, vehicles look consistent. Under the skin, they are optimised for different tasks.

This approach delivers consistency without sacrificing functionality.

Step Four: Use Modular Components to Enable Flexibility

Modularity is what makes standardisation work long term.

When storage systems are modular, fleets can:

- Swap components as roles evolve

- Reconfigure vehicles when technicians change roles

- Reuse fitouts across vehicle replacements

- Scale layouts across multiple sites

Modular drawers, adjustable shelving, and interchangeable accessories allow a single base design to support many use cases.

This also protects the fleet against future change. As tools, technology, and workflows evolve, the fitout can evolve with them.

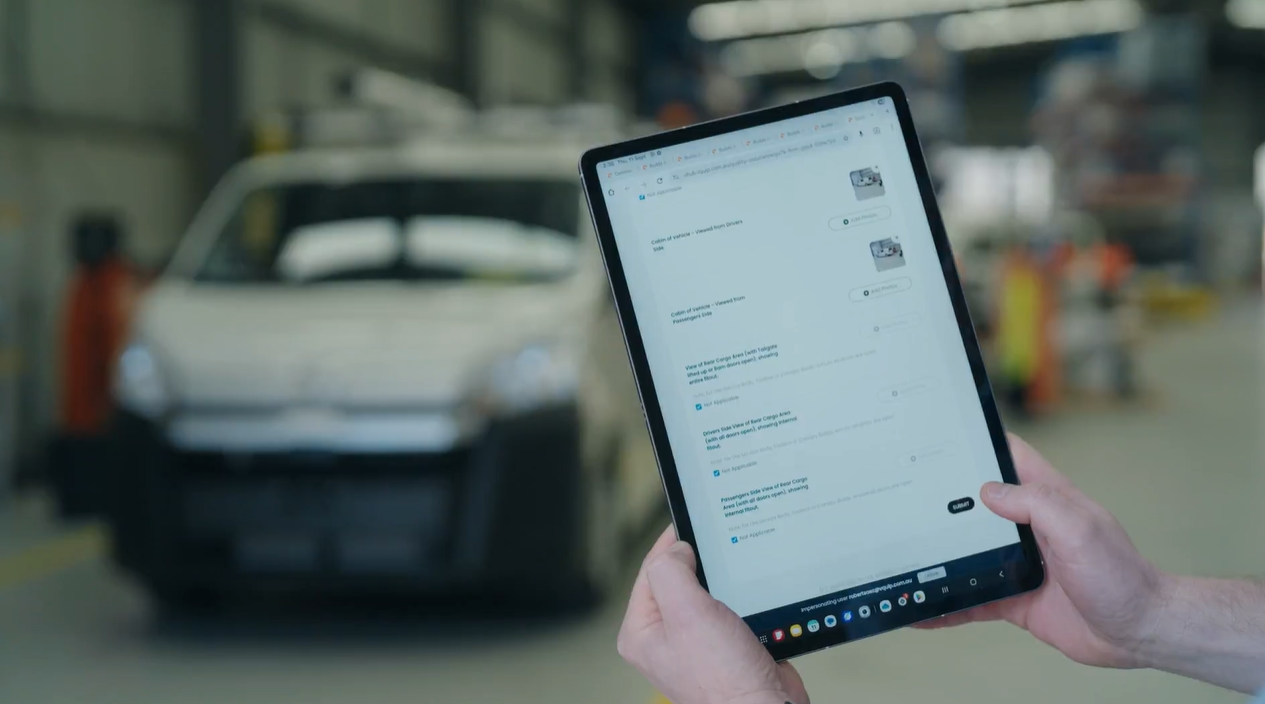

Step Five: Involve Technicians Early, Not at the End

One of the biggest mistakes fleets make is involving technicians only after designs are locked in.

High-performing fleets do the opposite. They gather structured input early and use it to inform design rules, not one-off exceptions.

Effective approaches include:

- Workshops with representative technicians

- Ride-along observations

- Feedback from incident reports and near misses

- Review of self-modified vehicles

- Data from tool usage and access frequency

This input helps identify what truly needs to vary by role and what can remain standard.

Technicians feel heard, and fleets avoid costly retrofits later.

Step Six: Lock Down Standards, Not Preferences

There is an important distinction between functional requirements and personal preferences.

Standardisation works best when fleets are clear about what is fixed and what is flexible.

Fixed elements might include:

- Shelving system and fixing points

- Safety equipment locations

- Load restraint methods

- Electrical capacity and protection

- Weight limits per zone

Flexible elements might include:

- Drawer depth selection

- Parts bin quantities

- Tool-specific holders

- Bench configurations

This clarity prevents fitouts from drifting over time while still allowing technicians to work efficiently.

Step Seven: Use Data to Refine Over Time

Standardisation is not a one-off decision. It is an ongoing process.

Large fleets that succeed treat fitout design as a living system. They track:

- Common modification requests

- Damage and wear points

- Overloaded zones

- Time lost accessing tools

- Safety incidents related to storage

These insights feed back into the next design iteration, improving both the standard platform and the role-specific templates.

Over time, the fleet becomes more efficient, safer, and easier to manage.

The Real Outcome: Consistency With Purpose

When done properly, standardising fleet fitouts does not remove individuality. It removes inefficiency.

Technicians get vehicles that support how they work. Fleet managers get predictability, control, and scalability. The business benefits from lower costs, faster rollouts, and reduced risk.

The key is understanding that standardisation is not about forcing every vehicle to be the same. It is about building a common foundation that allows smart variation where it genuinely adds value.

At VQuip, we help large fleets design fitout standards that scale nationally while still respecting the realities of different roles on the ground. The result is a fleet that looks consistent, works better, and adapts as the business grows.