Steel vs Aluminium Ute Trays: The pros and cons to get you on your way…

Jun 28, 2024

“Which is the better material for a drop side ute tray, steel or aluminium?” is a question that is often asked by tradies and fleet owners, and of course it’s one that’s especially relevant when you’re in the market for a tray for a new vehicle or refit! When it gets down to the nitty gritty, there’s really no one-size-fits-all answer to this one, but we’ve put together some pros and cons of each to help you get the best mileage out of your next tray.

Steel for strength in the toughest conditions

A good place to start with the comparison of steel vs aluminium and its suitability for a ute tray is to take stock of the type of business you’re in, what you use your vehicle for and the environments in which you operate.

Heavy-duty aluminium has come a long way in recent years and can often now stand the test when a high level of strength is required from your tray, however there’s no denying that steel is still a winner when it comes to ultimate durability. In an environment where heavy items are being dragged over the tray or it is subject to frequent or unrelenting bumps and thumps from tools or other items during daily use, steel has properties making it up to four times stronger than most grades of aluminium and will be less likely to be dented or damaged. Plus, if you are transporting rocks or other hard and jagged materials or freight, a steel tray could be the best option.

What about weight?

Weight is another important consideration when it comes to choosing between steel and aluminium. Steel trays can weigh upwards of two times as much as their aluminium equivalents which can be a real downside when it comes to the Gross Vehicle Mass (GVM). The kerb weight of your vehicle will be far less when an aluminium tray is fitted (compared with steel) therefore allowing greater payload capacity. Additionally, fitting a less weighty (but good quality) aluminium ute tray can make a huge difference to other factors of operating your vehicle such as fuel efficiency and reduced overall wear-and-tear. In instances where you may be looking for extra weight to stabilise lighter loads, steel could be a preferred option. Sometimes steel is also a good choice for cab-chassis vehicles, with the added weight of the steel tray complementing the suspension and ensuring you have a more comfortable ride when the ute is empty or the load is not at capacity.

Aluminium counters corrosion

Another big upside of aluminium is that it is resistant to corrosion, even in harsh coastal climates. While steel can be galvanised, powder coated or even painted to resist corrosion and rust, it can still be scratched leaving your tray looking shabby. Aluminium also therefore offers an advantage over steel being general lower maintenance when it comes to keeping it looking good in the face of wear in all-weather conditions.

Transporting flammable materials

Another pro of aluminium over a steel ute tray is that it is a safer option than steel if your business involves the transportation of flammable liquids, gases or other dangerous materials. Steel can spark in some situations, meaning it could be hazardous when transporting these types of items – so aluminium adds up as a good choice for safety reasons.

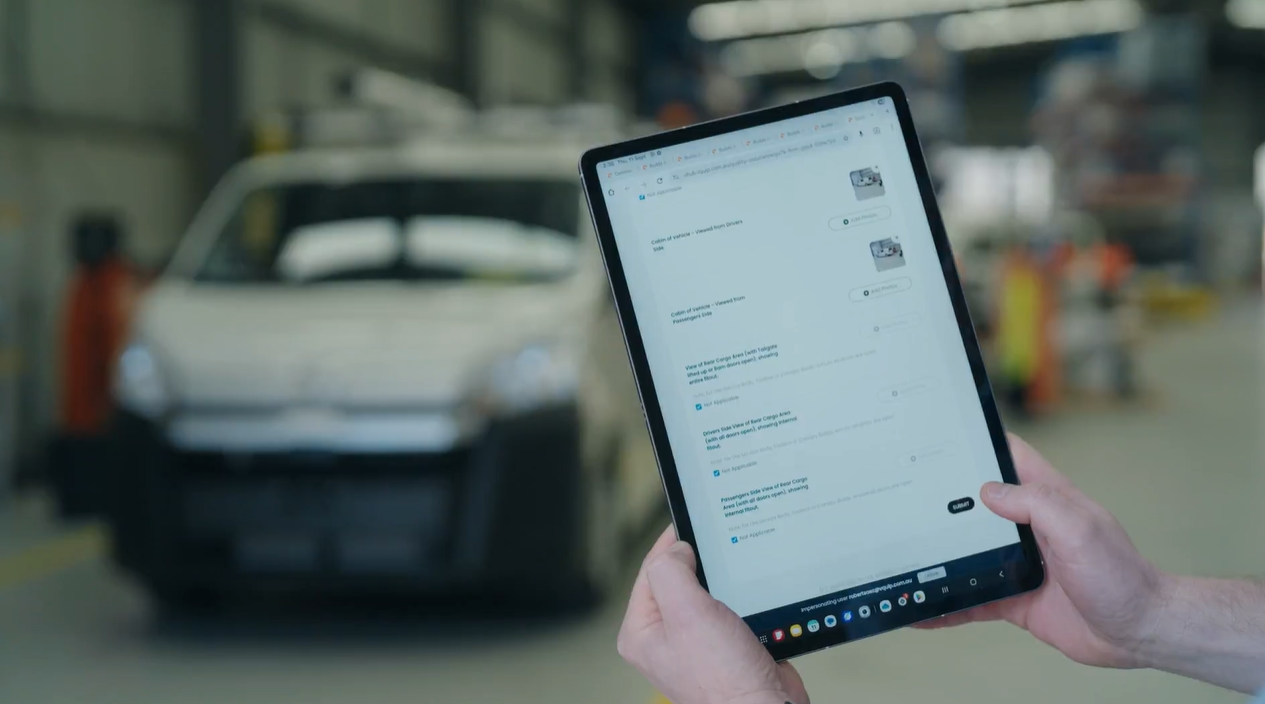

It all comes down to choice and quality

While there are usually many variables involved in whether an aluminium or steel tray is the right one for your vehicle/s, sometimes your choice may come down to something as simple as what looks best with your vehicle colour or company branding! To ensure you get a tray that best meets your requirements, always choose a supplier who stands by the quality of their products. VQuip’s range includes both superior heavy-duty aluminium as well as high quality steel ute trays, with our knowledgeable team well equipped to assist and offer advice to get your tray fitted and you on your way!