The 5-Minute Van Check: Daily Habits That Keep Your Fleet Lean and Safe

Sep 8, 2025

For many technicians, a work van is more than just a vehicle—it’s a mobile workshop, storage hub, and office rolled into one. But in the rush to get from site to site, it’s easy to overlook small habits that keep vans running smoothly, safe to operate, and organised for efficiency.

Enter the 5-Minute Van Check: a simple daily routine that blends Lean principles with practical fleet safety. With just a few minutes at the start (or end) of each day, your team can reduce downtime, avoid costly compliance issues, and make every job site run more efficiently.

Why a Daily Van Check Matters

-

Safety first: Spotting issues before they become hazards prevents accidents and breakdowns.

-

Lean efficiency: Maintaining order in the van ensures tools and parts are ready to go—no wasted time searching.

-

Fleet consistency: When every driver follows the same checklist, vehicles stay uniform and professional across sites and states.

-

Compliance: Regular checks reduce the risk of overloading, unsecured items, and missed maintenance obligations.

It’s not about adding more admin—it’s about creating habits that save time and money in the long run.

The 5-Minute Van Check: Step by Step

1. Walk-Around Safety Check (1 minute)

-

Look for visible damage, flat tyres, or fluid leaks.

-

Confirm all lights and indicators are working.

-

Check roof racks and external accessories are secure.

Why it matters: Small issues, left unchecked, can lead to costly roadside breakdowns or safety fines.

2. Load & Weight Awareness (1 minute)

-

Confirm heavy items are placed low and close to the bulkhead.

-

Ensure cargo is secured with straps, tie-downs, or mesh partitions.

-

Quick sense-check: is the van overloaded?

Why it matters: Staying under GVM avoids fines, protects the vehicle, and reduces the risk of rollovers or poor braking.

3. Tool & Parts Reset (1 minute)

-

Return any loose tools to their shelves, drawers, or bins.

-

Remove items not required for the day’s jobs.

-

Red flag anything damaged or missing.

Why it matters: A tidy van supports the Lean “Sort” principle—only carrying what’s needed improves speed and safety.

4. Cabin & Paperwork Tidy (1 minute)

-

Clear rubbish from the cab and windscreen.

-

Check that required compliance paperwork, manuals, or job sheets are accessible.

-

Ensure dash-mounted devices are secured, not loose.

Why it matters: A clean, clutter-free cab reduces distractions and presents a professional image to clients.

5. Quick Fuel & Fluids Check (1 minute)

-

Confirm fuel level—no surprises before a long job.

-

Glance at coolant, oil, and washer fluid indicators if accessible.

-

Check battery monitoring systems (if fitted).

Why it matters: A few seconds here saves hours of lost productivity if a van is forced off the road.

Embedding the Habit Across Your Fleet

A checklist is only effective when it’s part of the culture. Here’s how to make the 5-Minute Van Check stick:

-

Standardise the process: Roll out the same checklist to every driver and every site.

-

Train & explain: Make sure teams understand not just what to check, but why.

-

Use visual prompts: Place laminated 5-Minute Check cards on dashboards or inside van doors.

-

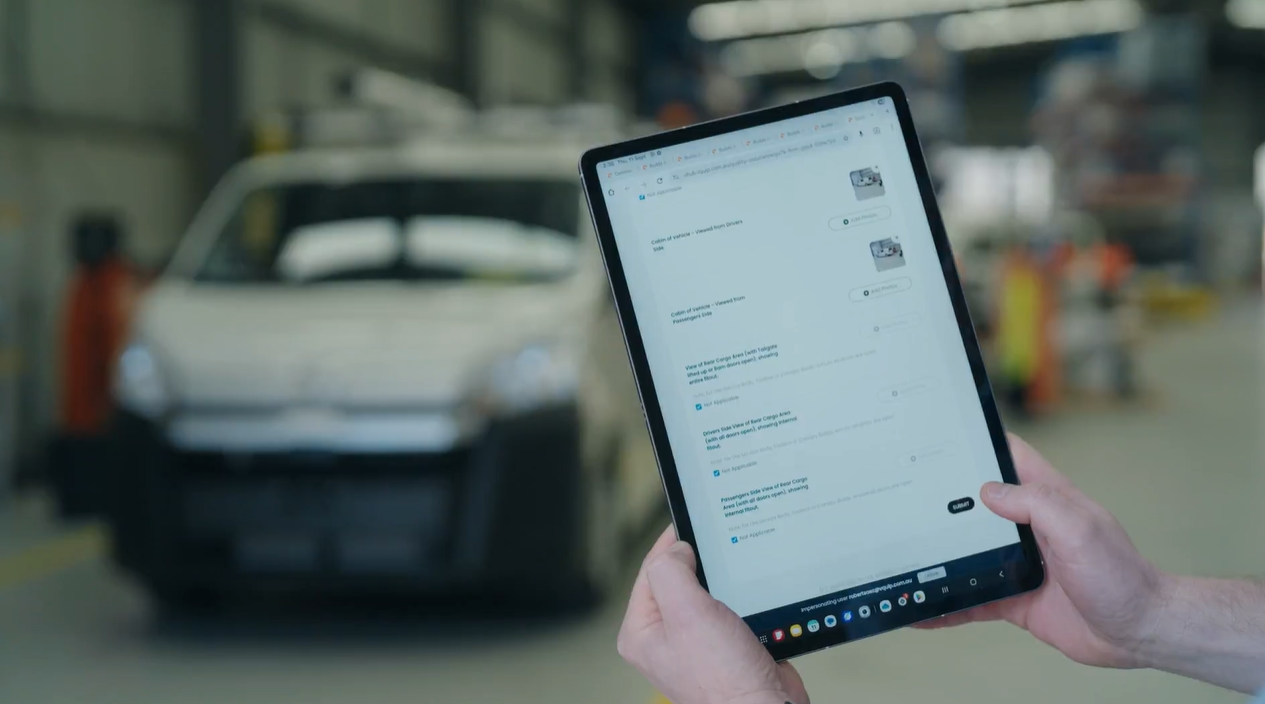

Leverage tech: Integrate the checklist into your fleet portal (like VHub) for easy tracking and accountability.

Lean, Safe, and Ready for the Road

When applied consistently, the 5-Minute Van Check does more than keep vehicles safe. It reinforces Lean habits, reduces unplanned downtime, and keeps your fleet looking professional and compliant.

It’s a small investment of time—just five minutes—that pays back in safety, efficiency, and customer confidence every single day.

👉 At VQuip, we help fleets go beyond compliance by designing fitouts that make daily habits like the 5-Minute Van Check effortless. Talk to us today about how our shelving systems, storage solutions, and VHub portal can make your fleet safer and leaner.