The 5S Van: Applying Lean to Mobile Workspaces

Aug 22, 2025

A step-by-step guide to Sort, Set in order, Shine, Standardise, Sustain for fleet vehicles

A work van or ute is a mobile workshop. When it is tidy, labelled, and laid out with intent, jobs start faster, errors drop, and the day feels easier. The 5S method brings the discipline of Lean into your vehicles so every technician can find, use, and return gear in seconds.

Here is a practical, fleet-ready playbook you can roll out across teams anywhere in Australia.

What is 5S and why use it in vehicles?

5S stands for Sort, Set in order, Shine, Standardise, Sustain.

It removes clutter, fixes layout, creates visual cues, and builds habits that stick. In vehicles, this means:

- Faster tool and parts retrieval

- Less stock loss and duplication

- Safer manual handling and access

- Consistent, professional setups across states and sites

1) Sort: keep only what earns its place

Goal: Remove anything that is not required for the current role, kit, or route.

How to do it

- 15-minute Red Tag sweep: Pull everything out. Tag anything you did not use in the last 30 days or cannot justify by task, compliance, or safety.

- Decide with data: Keep, Re-locate (to depot), or Dispose. Record quantities and conditions.

- Right-size the kit: If an item is used less than weekly, consider a shared pool at the depot.

- Weight awareness: Prioritise lightweight alternatives for infrequent items to protect payload.

Tips for trades

- Plumbing/HVAC: Rationalise duplicate fittings and keep only standard unions and reducers onboard. Store specialty parts in a labelled depot bin.

- Electrical/Comms: Consolidate consumables into colour-coded bins for low, medium, and high turnover.

2) Set in order: design the layout for flow and safety

Goal: A place for everything, designed around frequency of use and safe access.

Principles

- ABC zoning:

A = grab multiple times per job (front, waist-to-shoulder height)

B = used once per job (mid-bay drawers or shelves)

C = rarely used or bulky (roof racks, rear corners, under-tray) - One-motion rule: Common tools can be retrieved with one hand in one movement.

- Shortest path: Arrange items in the order you use them on a typical callout.

Practical choices

- Shelving and drawers: Fit adjustable shelves for bins and a lockable drawer stack for small tools. Use shadow foam or silhouettes for high-value tools.

- Bins and labels: Clear visi-bins with printed labels and part numbers. Add min/max markers inside each bin.

- Roof and rear access: Ladders on a drop-down rack, heavy items at knee height, never above shoulder height.

- Tie-downs and barriers: Use rated points, mesh or solid barriers, and straps for compressors, gas bottles, and bulky gear.

- Power and comms: Place the inverter, DC-DC charger, and GPOs where leads do not cross the doorway. Keep UHF head units and antennas mounted with thought for cable routing.

Output: A labelled map of the vehicle layout that any tech can follow.

3) Shine: clean, inspect, and reset to standard

Goal: The vehicle returns to the same “ready” state after every shift.

Daily 5-minute reset

- Rubbish out, surfaces wiped, floor swept or mat shaken

- Tools back to shadow spots, bins topped up if under the min line

- Quick check of lights, inverter, charger, and first-aid kit

Weekly 15-minute inspection

- Check straps, hinges, latches, and drawer slides

- Inspect seals, dust and water ingress points

- Confirm gas bottle vents are unobstructed

- Battery health check and visual on wiring

Create a simple Shine checklist laminated in the rear door. Tick it before finishing the day.

4) Standardise: lock in the winning setup across the fleet

Goal: Consistent layouts, labels, and replenishment rules so any tech can jump into any vehicle.

What to standardise

- Naming: One common language for shelves, bins, and tool locations. Example: S2-B3 = Shelf 2, Bin 3.

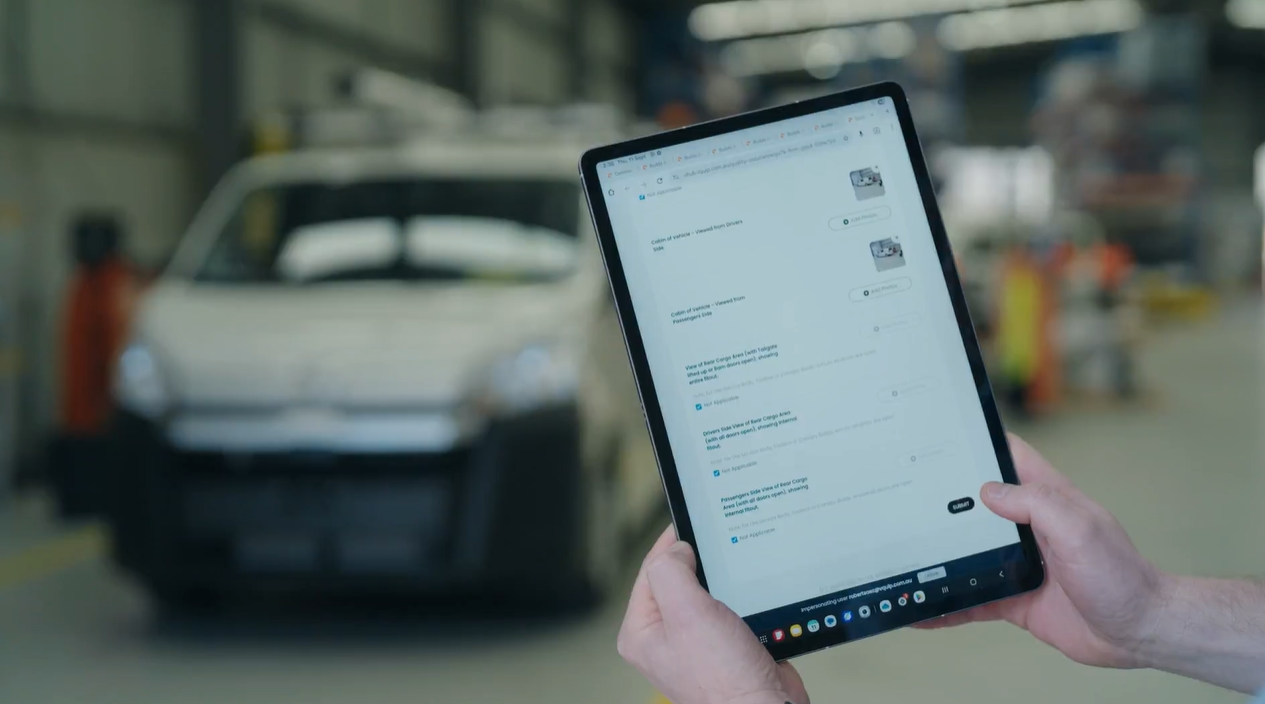

- Visuals: Photo guide or diagram in the rear door and cab. QR code links to the full layout and packing list.

- Replenishment: Min/max levels per consumable. A simple restock card or QR form triggers supply.

- Build variants: Start with an 80% standard kit and a 20% trade add-on pack for role differences.

- Documentation: Include the layout map, QA pack, and pre-start checklist in VHub or your chosen portal so everyone sees the same source of truth.

5) Sustain: make it habit, not a one-off tidy

Goal: Keep standards alive with simple routines and light governance.

How to sustain

- Ownership: Assign a vehicle captain. Their name is on the checklist and the VHub page.

- Audits: 10-minute monthly audit with a pass score posted in the cab.

- Onboarding: New starters get a 5S walk-through and a 30-day follow-up.

- Coaching, not blaming: If something is out of place, fix the layout or the label before blaming the person.

- Continuous improvement: Keep a running list of annoyances. Trial one improvement per month and standardise if it works.

Rollout plan for fleets

Week 1: Pilot

- Select 3–5 vehicles from one region and one trade.

- Run Sort and Set in order with the team.

- Finalise layout map, labels, and min/max levels.

- Upload layout and checklists to VHub or your central system.

Week 2: Prove and scale

- Track time to first-fix, search time for top 10 items, and stockouts.

- Run Shine and a first audit at end of week.

- Adjust, then replicate across the rest of the fleet by trade group.

What to measure

Pick simple metrics that show value quickly:

- Search time: Average seconds to find a top-10 item

- First-fix rate: Jobs completed without a depot run

- Stock accuracy: Count of bin stockouts per week

- Damage and warranty: Incidents from unsecured loads or poor access

- Audit score: Monthly 5S score per vehicle

Use a small dashboard so improvements are visible and rewarding.

Suggested kit for a 5S-ready van or ute

- Adjustable shelving with labelled bins and dividers

- Lockable drawer units with shadow foam inserts

- Mesh or solid barrier, rated tie-down points and straps

- Drop-down ladder rack or safe access system

- Whiteboard or laminated checklist at rear door

- QR labels that link to layout map, packing list, and restock form

- DC-DC charging, inverter, and protected cable paths

Quick checklist you can copy

- Remove duplicates and seldom-used items

- Zone A/B/C based on frequency of use

- Label everything with the same naming scheme

- Set min/max on consumables and restock method

- Daily 5-minute reset and weekly 15-minute inspection

- Monthly 10-minute audit with a visible score

- One improvement trialled every month

Wrap-up

5S turns every vehicle into a consistent, efficient workspace. Start small, prove it on a few vehicles, then standardise the winning design across the fleet. If you would like, I can turn this into a downloadable checklist and a one-page SOP for your team, or tailor a “standard kit plus trade add-on pack” for specific roles.