The Science of Storage: How Layout Impacts Technician Efficiency

Nov 9, 2025

When it comes to vehicle fitouts, storage isn’t just about where things go; it’s about how people work. A well-designed layout can shave minutes off every task, reduce fatigue, and create a safer, more productive environment for your team. Across a fleet, that efficiency adds up to real time and cost savings.

Why Storage Design Matters

Every van or ute is a mobile workspace. The layout determines how technicians move, access tools, and perform their jobs. A poorly organised fitout can lead to wasted motion, awkward reach zones, and unnecessary trips back to the depot. In contrast, a layout that follows proven ergonomic and workflow principles enables technicians to work faster, safer, and with less strain.

Applying Lean 5S to Fitout Design

An efficient vehicle layout follows the same principles used in high-performing workshops and production lines. The Lean 5S framework — Sort, Set in Order, Shine, Standardise, Sustain — provides a simple, proven structure for keeping workspaces organised and productive.

-

Sort: Remove clutter and unnecessary equipment from the vehicle.

-

Set in Order: Group tools and parts by task or frequency of use.

-

Shine: Keep work areas clean and easy to maintain.

-

Standardise: Use consistent layouts across vehicles to reduce training time and confusion.

-

Sustain: Build habits that help technicians maintain order every day.

Applied to fleet fitouts, 5S helps ensure technicians can access what they need quickly, stay focused on the job, and keep vehicles safe and tidy.

Designing for Reach and Accessibility

Technicians access their vehicles hundreds of times a week. Small ergonomic improvements make a big difference over time.

-

Frequent-use items should be stored between knee and shoulder height to minimise bending or reaching.

-

Heavy tools should be positioned close to doors or slides to reduce lifting strain.

-

Drawers and shelving systems should open smoothly and allow full visibility of contents.

-

Lighting and labelling help reduce search time and frustration in low-light conditions.

A few seconds saved per task might not seem like much, but across dozens of jobs each day, the impact compounds quickly.

The Power of Standardisation

For larger fleets, standardising storage layouts across vehicle types is a simple way to boost efficiency and reduce downtime. When every technician knows exactly where to find key items, they can move between vehicles seamlessly. This is ideal for shared fleets, multi-region rollouts, or relief staff.

Standardisation also simplifies procurement, maintenance, and training. And because every fitout meets the same quality and safety benchmarks, it’s easier to ensure compliance with ADR and WHS requirements.

Safety and Weight Distribution

Efficiency isn’t just about speed; it’s also about control. Correct weight distribution across axles ensures vehicles remain stable under load, especially during braking and cornering. Poorly balanced storage can cause uneven tyre wear, impact handling, or even create safety risks.

VQuip’s shelving and drawer systems are engineered to keep weight low and evenly distributed, maintaining performance and safety without compromising access or storage capacity.

Efficiency You Can Feel on the Job

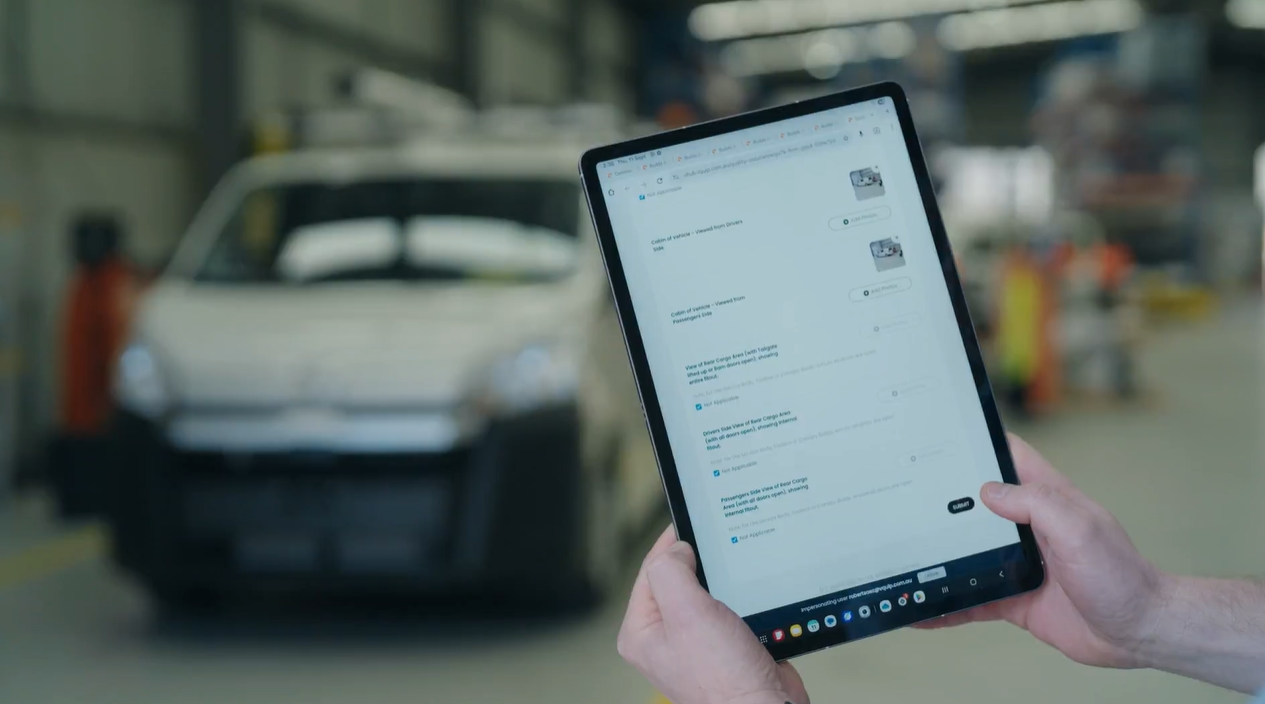

The right layout means fewer trips, faster task completion, and less fatigue by the end of the day. For technicians, it’s a smoother, safer way to work. For fleet managers, it’s measurable productivity and consistency across every vehicle.

At VQuip, we don’t just design storage; we engineer efficiency.

Our shelving, drawer, and racking systems are built to streamline workflow, protect your team, and make every vehicle a better workplace.