Top Mistakes to Avoid When Rolling Out a New Fleet of Fitouts

Jul 15, 2025

Outfitting a commercial vehicle fleet is a significant investment, and getting it wrong can have lasting consequences—from safety issues and vehicle downtime to inefficient workflows and compliance risks. Whether you’re sourcing five vans or rolling out 500, there are common missteps that can derail the process or inflate long-term costs.

At VQuip, we’ve worked with fleet managers, procurement teams, and leasing companies across Australia, and we’ve seen firsthand what works—and what doesn’t.

Here are the top mistakes to avoid when sourcing new vehicle fitouts, and how to steer clear of them.

- Not Involving End Users in the Planning Process

Too often, fitout decisions are made in boardrooms without input from the technicians or drivers who will use the vehicles every day. The result? Inefficient layouts, awkward access, or tools stored in the wrong place—ultimately slowing your team down.

What to do instead:

Engage your field staff early. Even a short survey or site walk-through can uncover practical needs—like extra lighting, better access to commonly used tools, or specialised storage that makes a real difference.

- Choosing the Cheapest Quote Without Considering Long-Term Value

While cost is always a consideration, the cheapest option can often cost more in the long run. Inferior materials, poor installation quality, and a lack of after-sales support can lead to equipment failures, vehicle downtime, and safety risks.

What to do instead:

Look beyond the price tag. Compare warranties, materials used, QA processes, and the provider’s ability to scale with your needs. Investing a little more upfront often results in a more durable, compliant, and cost-effective solution over the life of the vehicle.

- Ignoring Payload and GVM Limits

Every fitout adds weight to your vehicle. Overloading a van or ute can lead to non-compliance with GVM regulations, increased wear and tear, and even voided insurance claims.

What to do instead:

Ensure your fitout provider understands weight distribution and GVM compliance. Be sure to factor in total fitout weight, passenger load, tools, and cargo—so your setup stays within legal and safe limits.

- Over-Customising Every Vehicle

Customisation is great—until it creates inconsistency across your fleet. Unique layouts for each vehicle may suit individuals, but they complicate maintenance, training, and inventory stocking.

What to do instead:

Establish standardised fitout templates by trade or role. This makes onboarding faster, reduces servicing complexity, and improves operational efficiency—especially when vehicles are rotated between team members.

- Underestimating the Importance of QA and Documentation

A well-built fitout should be backed by thorough quality assurance. Without documentation—such as installation checklists, compliance sign-offs, and photographs—you may face disputes or delays later.

What to do instead:

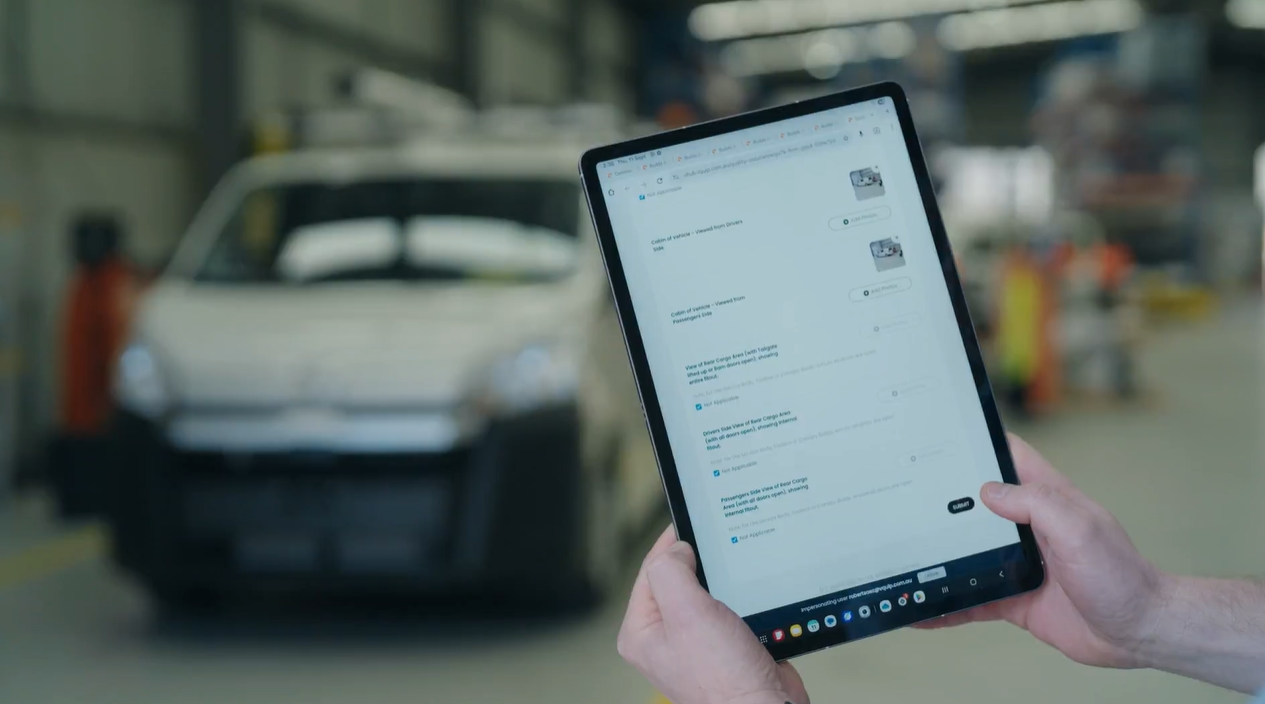

Work with a provider that offers digital QA processes. At VQuip, we log every stage of the build and give customers full access via our VHub portal, so nothing slips through the cracks.

- Rushing the Project Timeline Without a Clear Rollout Plan

Trying to fast-track your fleet fitouts without proper planning can lead to errors, missed specifications, or unavailable parts.

What to do instead:

Establish a realistic rollout timeline, especially if you’re coordinating multiple vehicles across different locations. Choose a provider with proven project management systems in place, including ETA tracking, purchasing workflows, and communication touchpoints.

- Not Planning for the Future

Vehicles evolve. So do the needs of your business. Fitouts that are too rigid or purpose-built without flexibility may limit how the vehicle can be used down the track.

What to do instead:

Think modular. Opt for shelving, drawer systems, and storage solutions that can be adapted, moved, or reused. This is especially important if your business expands or shifts focus—or if you’re preparing for an EV transition.

Final Thoughts

Getting your fleet fitouts right from the start saves time, avoids costly mistakes, and helps your team stay productive and safe on the road. But that only happens when you take a strategic, informed approach to sourcing and design.

At VQuip, we go beyond just installing shelves and drawers. We help you design fitouts that are safe, compliant, efficient, and ready for the future. And with tools like our VHub portal, you get full visibility of your rollout—from QA photos and documentation to real-time progress updates.

Need help getting your next fleet fitout right?

Speak with the team at VQuip to explore VHub and see how we bring full transparency to your future vehicle builds.