Van vs Ute: Why More Australian Fleets Are Choosing Vans for Mobile Workspaces

Dec 18, 2025

Utes have long been the default work vehicle across Australia. From construction sites to regional service routes, the ute has built a reputation for toughness, versatility, and off-road capability. For many businesses, the choice has become automatic.

But as fleet operations evolve, and as productivity, safety, and whole-of-life costs come under closer scrutiny, many organisations are starting to ask an important question:

Is a ute really the best tool for the job, or is a van the smarter long-term choice?

For service-based fleets, technicians, and mobile trades, vans are increasingly proving to be the more efficient, safer, and cost-effective platform. Here’s why.

- Protection From Weather and the Elements

One of the biggest advantages a van has over a ute is full enclosure.

Tools, parts, consumables, and specialist equipment are all protected from rain, dust, UV exposure, and extreme temperatures. Over time, this protection significantly reduces corrosion, degradation, and premature replacement of tools and materials.

With open trays and external toolboxes, utes often rely on seals and covers that are exposed to constant wear. Even high-quality canopies struggle to fully eliminate moisture ingress over years of daily use.

For fleets operating year-round, in all conditions, a van offers a far more controlled and durable environment.

- Improved Security and Reduced Theft Risk

Tool theft is a major cost for Australian businesses. Vans inherently reduce this risk.

An enclosed cargo area removes visual access to tools and materials, reducing opportunistic theft. Internal locking systems, deadlocks, and integrated shelving further enhance security without relying on exposed external boxes.

Utes, particularly those with open trays or canopy windows, are more visible targets. Even well-secured toolboxes are often accessible from outside the vehicle.

For fleet managers, fewer theft incidents mean less downtime, lower insurance claims, and better operational continuity.

- Organisation and Productivity Gains

A van is essentially a mobile workspace. When fitted out correctly, it allows tools, parts, and equipment to be stored in clearly defined zones.

Shelving, drawers, parts bins, and racking systems enable technicians to:

- Find tools faster

- Reduce time spent searching

- Maintain consistent layouts across fleets

- Apply lean and 5S principles to mobile workspaces

In contrast, utes often rely on floor-level storage, stacked boxes, or multiple external compartments. This can lead to inefficiencies, clutter, and inconsistent layouts between vehicles.

Over the course of a working week, even small time savings per job add up quickly.

- Safer Load Restraint and Compliance

Load restraint is a critical safety consideration, particularly in a collision or sudden braking event.

Vans allow loads to be restrained internally using purpose-designed systems, including crash-tested shelving that meets Australian standards. Items are less likely to shift, fall, or become projectiles.

With utes, especially open trays, load restraint relies heavily on straps, cages, or covers that may not always be used consistently in day-to-day operations.

For safety-focused fleets, vans offer a more controlled and compliant environment for transporting equipment.

- Payload Efficiency and Weight Distribution

While utes are often perceived to have higher payload capacity, real-world usability tells a more nuanced story.

Vans typically offer better payload efficiency, meaning the weight carried is distributed more evenly across the vehicle. Shelving systems keep loads low and balanced, improving handling, braking, and tyre wear.

Utes, particularly with heavy tray setups, can become rear-biased very quickly. This affects ride quality, suspension wear, and overall vehicle stability.

For fleets that carry tools, parts, and consumables rather than bulk materials, vans often provide a more practical and safer payload solution.

- Technician Comfort and Ergonomics

Technicians spend long hours in and around their vehicles. Comfort and ergonomics matter.

Vans offer:

- Lower step-in heights

- Less climbing and reaching

- Better internal lighting

- Weather-protected access

These factors reduce fatigue and physical strain over a full workday. Over time, better ergonomics contribute to improved job satisfaction and reduced injury risk.

Utes, by nature, require more bending, lifting, and climbing, particularly when accessing tray-mounted storage.

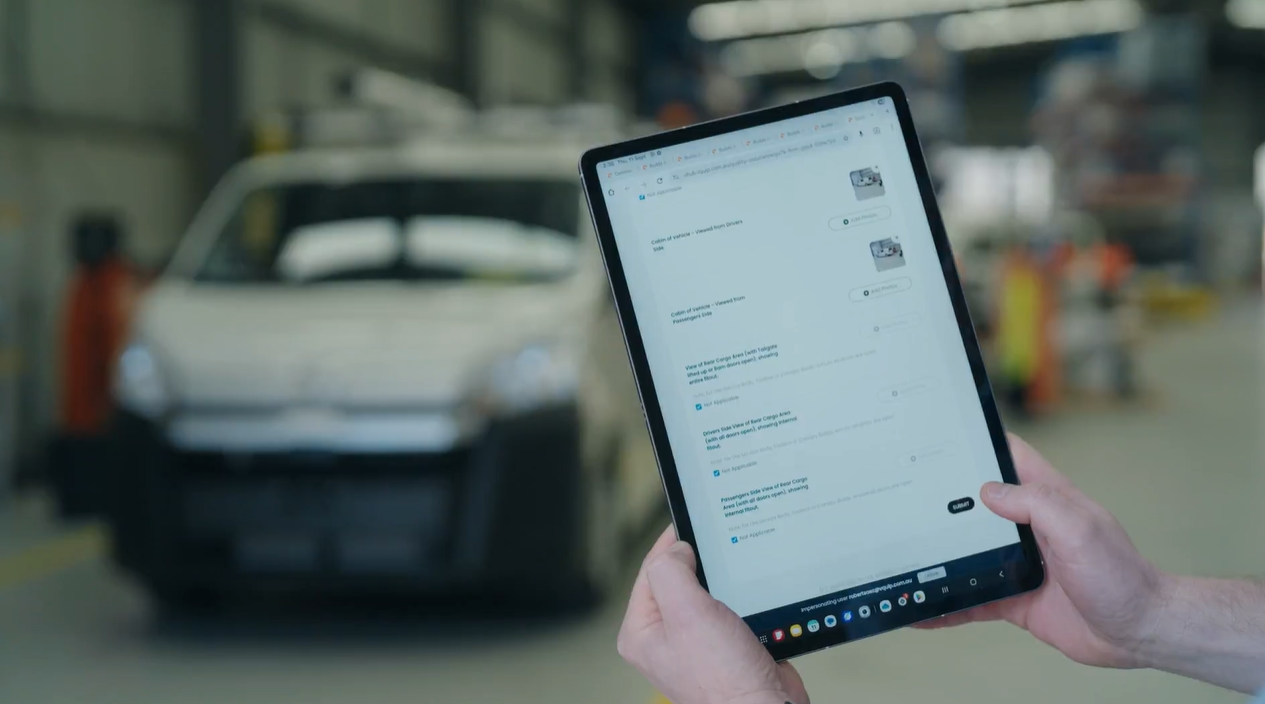

- A True Mobile Workshop

For many service roles, the vehicle is not just transport. It’s a workshop.

Vans enable the integration of:

- Workbenches and vices

- Battery charging stations

- Parts storage

- Diagnostic equipment

- Internal power systems

This allows technicians to prepare, repair, and complete tasks on site without constant trips back to depots or warehouses.

While utes can support some of these functions, they rarely offer the same level of protection, organisation, or usability.

- Professional Image and Brand Consistency

First impressions matter.

A well-presented van fleet provides a clean, professional appearance at customer sites. Vans also offer a larger, uninterrupted surface for branding, signage, and fleet identification.

Open trays and exposed equipment can sometimes appear cluttered or inconsistent, particularly across larger fleets.

For customer-facing businesses, vans help reinforce professionalism, reliability, and trust.

- Whole-of-Life Cost Advantages

When considering total cost of ownership, vans often outperform utes in service-based roles.

Key factors include:

- Reduced tool replacement due to weather exposure

- Lower theft risk

- Less wear on equipment

- Improved resale value

- Fitouts that can be transferred between vehicles

While initial vehicle selection may appear similar on paper, long-term operating costs often favour vans for many fleet applications.

- When a Ute Is Still the Right Choice

This is not about replacing utes entirely.

Utes remain the best option for:

- Dirty or abrasive materials

- Landscaping, concreting, and earthworks

- Tipping or crane-based operations

- Oversized or irregular loads

- Remote or heavy off-road conditions

The key is matching the vehicle platform to the actual job requirements, rather than defaulting to habit.

Making the Right Choice for Your Fleet

Choosing between a van and a ute is not about preference. It’s about productivity, safety, compliance, and whole-of-life value.

For many service-based fleets, vans offer clear advantages as mobile workspaces. When combined with a purpose-designed fitout, they can transform how technicians work day to day.

At VQuip, we help fleet operators assess the right vehicle platform before the first shelf is ever designed. The result is a fleet that works harder, safer, and smarter.