What “Build Transparency” Actually Looks Like in a National Fleet Rollout

Feb 2, 2026

In theory, national fleet rollouts should be predictable. Vehicle specifications are agreed, suppliers are selected, timelines are set, and production begins.

In practice, many fleet managers discover that once vehicles enter the fitout phase, visibility drops away. Updates become infrequent, information is fragmented, and answers to simple questions such as “Where is my vehicle?” or “What stage is it at?” are harder to get than they should be.

This gap between expectation and reality is where build transparency matters.

But transparency is often discussed vaguely. This article breaks down what build transparency actually looks like in a real national fleet rollout, and why it matters beyond convenience.

The Problem With Traditional Fleet Rollouts

Large fleet rollouts typically involve multiple vehicles, multiple locations, and multiple stakeholders. Vehicles may be sourced from different dealers, fitted out across different states, and delivered on staggered timelines.

In many cases, fitout updates rely on:

- Manual email updates

- Phone calls to individual build sites

- Spreadsheets that quickly become outdated

- Status descriptions that are open to interpretation

The result is uncertainty. Fleet managers are left chasing information, internal teams struggle to plan handovers and commissioning, and small issues can remain unnoticed until vehicles arrive.

True build transparency is about removing this uncertainty.

What Build Transparency Actually Means

Build transparency is not just about receiving updates. It is about having clear, consistent, and verifiable information at every stage of the build.

In a national fleet rollout, real transparency includes:

- Clear Production Status Definitions

Every vehicle should move through clearly defined build stages that mean the same thing across all locations.

When statuses are standardised, fleet managers can immediately understand progress without needing clarification.

- Real-Time or Near Real-Time Progress Visibility

Transparency improves dramatically when fleet managers can see progress as it happens, rather than waiting for periodic updates.

This allows:

- Earlier identification of delays

- Better coordination with vehicle delivery, registration, and deployment

- More accurate internal reporting

It also removes the need to chase updates, freeing up time for higher-value work.

- Visual Proof, Not Just Written Updates

One of the most overlooked aspects of build transparency is visual confirmation.

Photographic records after the build has been completed provide:

- Confidence that the specified fitout has been completed correctly

- Evidence that components are installed as designed

- A clear reference point for internal sign-off and future audits

For interstate fleet managers, this is especially important. Photos allow them to review builds without needing to physically inspect vehicles in another state.

- Quality Assurance That Is Documented and Accessible

Transparency is incomplete without visible quality assurance.

A transparent rollout includes:

- Documented QA checks

- Photos of completed installations

- Confirmation that safety-critical items are installed and secured correctly

This not only supports compliance, but also provides a record that can be referenced months or years later if questions arise.

- Consistency Across States and Build Locations

National fleets often struggle with inconsistent outcomes between locations. Transparency helps identify and prevent this.

When builds are tracked and documented in the same way across all sites, it becomes easier to:

- Maintain consistent fitout quality

- Identify variations early

- Ensure every vehicle meets the same standard before release

Consistency is not achieved by assumption. It is achieved through visibility.

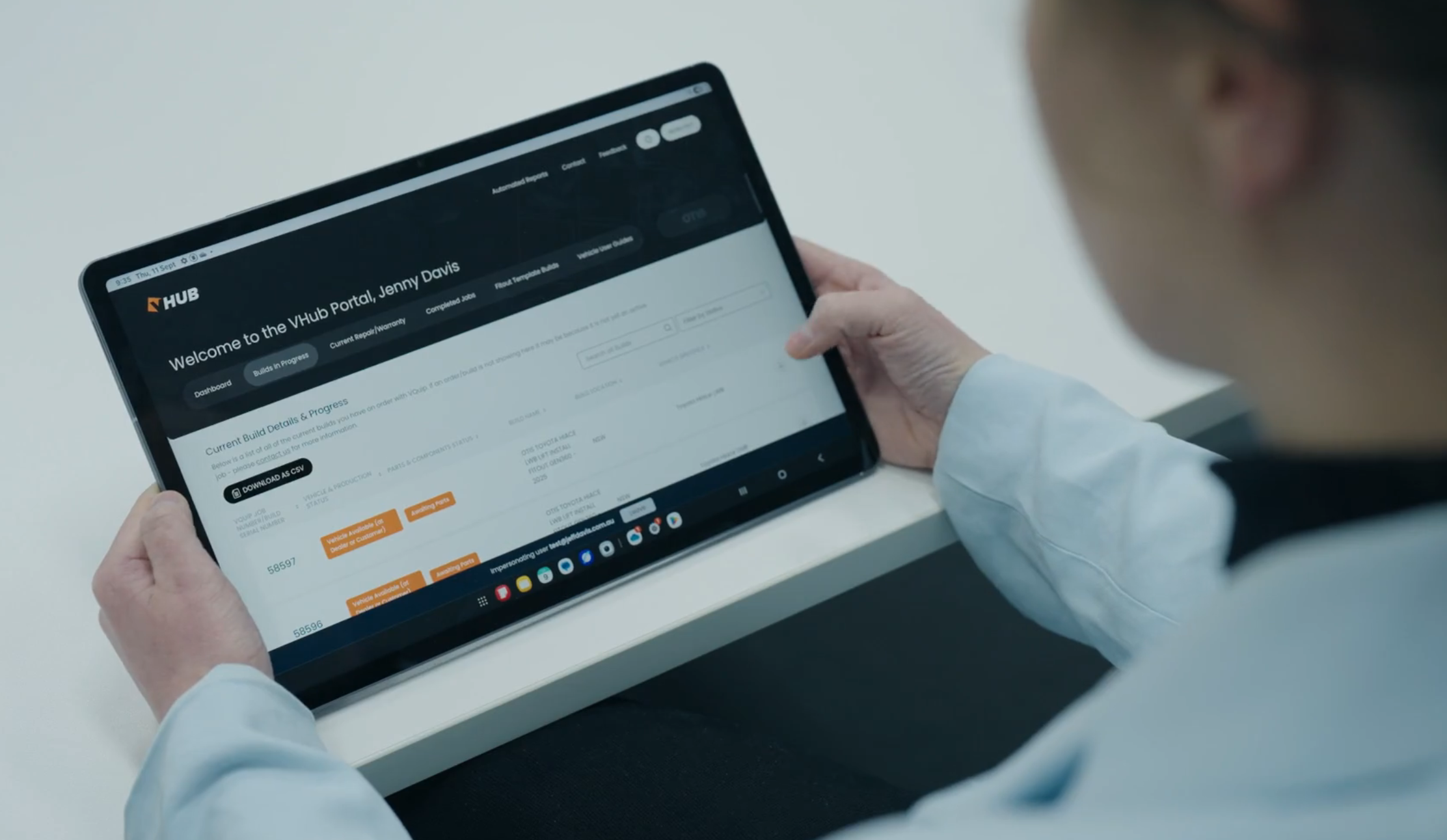

- A Single Source of Truth

One of the biggest causes of confusion in fleet rollouts is fragmented information.

True build transparency relies on a single, central source where:

- Build status is updated

- QA documentation is stored

- Photos and notes are accessible

- Stakeholders can check progress at any time

This reduces miscommunication and ensures everyone is working from the same information.

Why Build Transparency Matters Beyond Convenience

Build transparency is often framed as a “nice to have”. In reality, it has direct operational and financial implications.

Transparent rollouts support:

- Better deployment planning

- Faster issue resolution

- Reduced rework and post-delivery corrections

- Greater confidence in compliance and safety outcomes

They also build trust. When fleet managers can clearly see what is happening with their vehicles, uncertainty is replaced with confidence.

What Fleet Managers Should Look For

When planning a national fleet rollout, fleet managers should ask potential fitout partners:

- How will I see build progress across all locations?

- How are build stages defined and communicated?

- Will I receive photographic QA documentation?

- Is there a central system where all information is stored?

- How do you ensure consistency across states?

The answers to these questions will quickly reveal whether transparency is a genuine capability or simply a marketing phrase.

Transparency as a Foundation, Not an Extra

National fleet rollouts are complex by nature. Build transparency does not remove complexity, but it makes it manageable.

When visibility is built into the process from the start, fleet managers gain control, confidence, and clarity. And in large-scale fleet operations, those qualities are not optional.

They are essential.