What Happens When Procurement Chooses on Price Alone

Feb 19, 2026

In any national fleet rollout, procurement plays a critical role.

Budgets must be managed.

Comparisons must be fair.

Value must be demonstrated.

But when a fleet fitout decision is made on price alone, without properly evaluating what sits behind that price, the long-term consequences can outweigh the short-term savings.

A commercial vehicle fitout is not simply a purchase of accessories. It is the creation of a mobile workplace — one that affects safety, productivity, compliance exposure, operational control and asset value for years.

Here’s what often happens when cost becomes the only decision driver.

- “Like-for-Like” Quotes Rarely Are

On paper, two proposals may appear comparable:

- Shelving

- Drawer systems

- Roof racks

- Electrical components

- Service bodies

But the real differences are usually hidden in the detail:

- Mounting methods

- Material grade

- Engineering documentation

- Installation process control

When price becomes the primary filter, those differences are often overlooked.

The result can be a cheaper build that looks similar on delivery day, but performs very differently over time.

- Engineering Gets Reduced to Installation

There is a significant difference between:

- Installing accessories, and

- Engineering a fitout system.

A lower-cost proposal may rely on generic mounting points, minimal reinforcement, or limited design validation.

In the event of a serious accident, questions may arise around:

- Load restraint compliance

- Barrier integrity

- Mounting strength

- Weight distribution

- Electrical installation standards

If these elements were not engineered properly at the outset, the operational risk ultimately sits with the vehicle operator — not the installer.

Fitouts must be designed as integrated systems, not assembled as accessory lists.

- Hidden Lifecycle Costs Start to Appear

The cheapest upfront option can become the most expensive over five years.

Common downstream costs include:

- Drawer failures

- Shelf deformation

- Corrosion in harsh environments

- Electrical faults

- Rework to address technician complaints

- Mid-cycle modifications

When fleets operate dozens or hundreds of vehicles, even minor reliability issues multiply quickly.

Downtime is rarely captured in the procurement spreadsheet. But operational disruption directly affects service delivery and revenue.

Lifecycle performance matters more than acquisition cost.

- Technician Acceptance Drops

If a fitout has been selected purely on price — without meaningful technician input or prototype validation — the impact is often felt in the field first.

Typical signs include:

- Improvised storage solutions

- Aftermarket additions

- Removal of poorly positioned components

- Workarounds that compromise safety

This is how “spec drift” begins — gradual variation away from the approved master specification.

Standardisation only works when the standard genuinely works.

If technicians are not aligned with the layout, consistency across a national fleet becomes difficult to maintain.

- Compliance and Documentation Gaps Surface Later

Fleet fitouts must align with:

- WHS obligations

- Load restraint expectations

- Corporate safety policies

- Internal governance requirements

Lower-cost proposals sometimes reduce investment in:

- Detailed documentation

- QA records

- Photo logs

- Structured installation checklists

These gaps may not be visible at purchase stage, but they become critical during:

- Incident investigations

- Internal audits

- Insurance reviews

- Fleet transitions

Documentation is not an administrative add-on. It is risk protection.

- National Consistency Becomes Difficult

For organisations operating across multiple states, price-driven procurement can lead to:

- Different installers

- Different mounting methods

- Variation in electrical layouts

- Inconsistent safety labelling

- Uneven build quality

Even when the parts list is identical, execution may not be.

Consistency requires controlled processes and centralised oversight — not just competitive pricing.

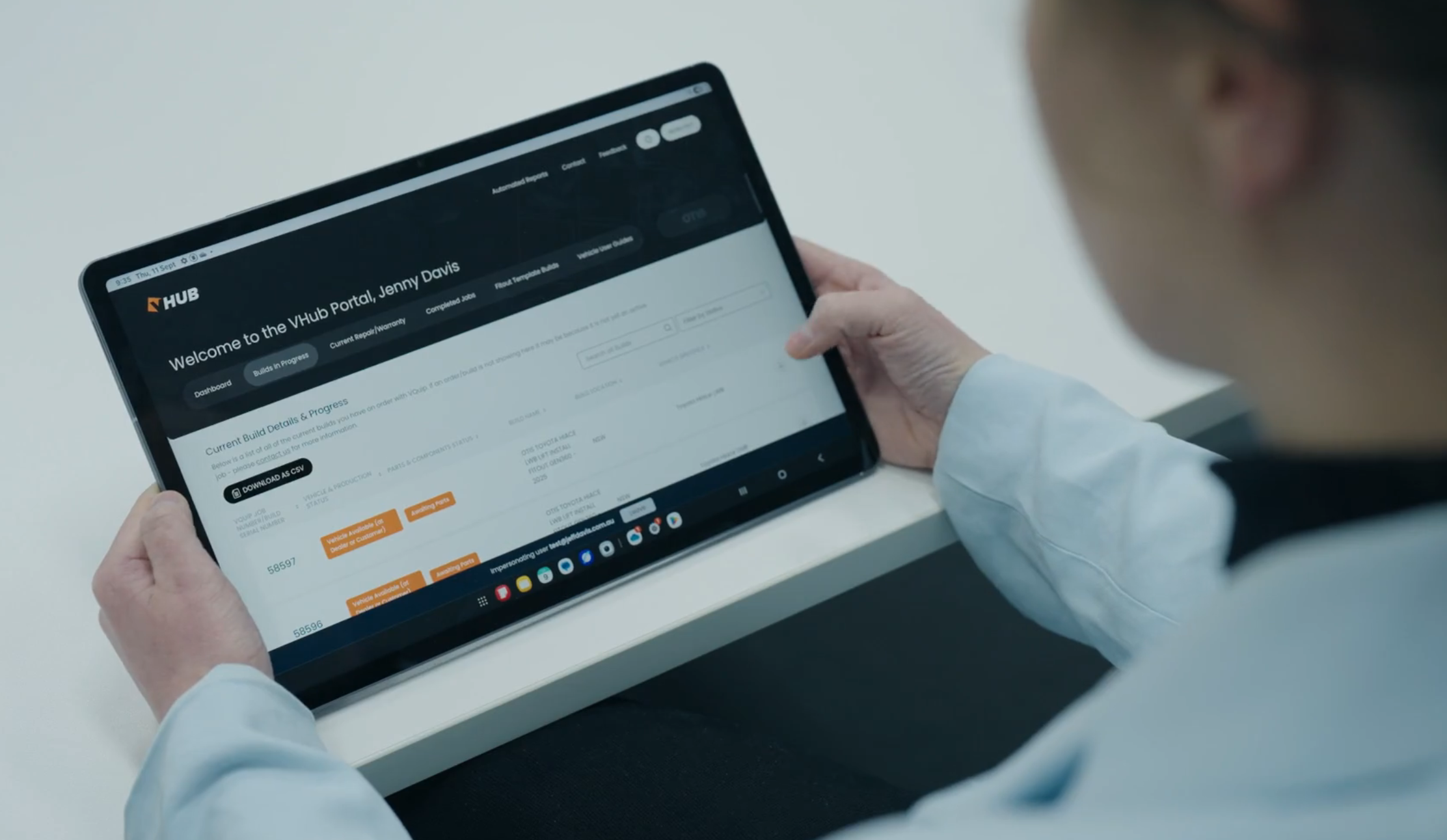

- The Hidden Cost of Poor Rollout Visibility

When procurement selects purely on price, one of the first areas that often gets reduced is process control and rollout transparency.

Lower-cost providers may not offer:

- Structured production scheduling

- Clear stage tracking

- Real-time build updates

- Dedicated project coordination

- QA documentation during build

At first glance, this may appear secondary.

In practice, it creates operational friction.

Fleet managers often find themselves:

- Chasing build updates via email

- Calling to confirm vehicle status

- Coordinating transport with incomplete information

- Managing uncertainty across multiple regions

That time has a cost.

When rollout visibility drops, the downstream financial impact can include:

Extended Vehicle Leases

If replacement vehicles are not delivered on time, existing leases may need to be extended.

Even short-term extensions can add significant unplanned cost across a large fleet.

Idle Capital

Vehicles delivered but not yet fitted out represent capital sitting unproductive.

Technician Scheduling Disruption

Unclear delivery timing affects workforce allocation and service planning.

Administrative Overhead

Internal teams spend hours following up information that should be proactively available.

In national rollouts involving dozens or hundreds of vehicles, these inefficiencies compound quickly.

Rollout visibility is not just a convenience feature — it is cost control.

- Residual Value Is Affected

Fleet vehicles eventually transition to:

- Auction

- Trade resale

- Internal redeployment

Fitouts that are poorly integrated, heavily modified, or prematurely worn can reduce resale value and increase decommissioning costs.

Quality systems that remain structurally sound and well-documented tend to present better at disposal stage.

Residual value is rarely factored into the initial procurement decision — but it should be.

- The Illusion of Savings

If a fitout is $1,500 cheaper per vehicle across 100 vehicles, that appears as a $150,000 saving.

But if:

- Productivity drops

- Downtime increases

- Warranty claims rise

- Field retrofits are required

- Lease extensions are triggered

- Administrative overhead increases

The operational cost can quickly exceed the original saving.

Fleet fitouts are operational infrastructure. Infrastructure decisions should be evaluated on total lifecycle performance — not acquisition cost alone.

A More Balanced Procurement Approach

Price absolutely matters.

But it should sit within a broader evaluation framework that considers:

- Engineering integrity

- Compliance credentials

- Installation control

- Documentation standards

- Technician workflow alignment

- Rollout visibility

- National capability

- Lifecycle durability

A procurement decision that weighs these factors does not ignore cost — it contextualises it.

Final Thought

Choosing purely on price often delivers exactly what was purchased: the lowest-cost option.

The challenge is that fleet fitouts influence safety outcomes, technician productivity, downtime, asset value and compliance exposure for years.

When procurement evaluates beyond the headline figure, fleets typically achieve:

- Stronger standardisation

- Fewer modifications

- Lower lifecycle costs

- Better safety performance

- Greater rollout control

In commercial fleet fitouts, the cheapest option is rarely the lowest-cost decision.