What’s the True Cost of Downtime? Why Fitouts Play a Bigger Role Than You Think

May 16, 2025

For any business that relies on vehicles to get the job done, keeping your fleet on the road isn’t just about convenience—it’s critical to your bottom line. Every hour a van, ute, or service vehicle is off the road represents lost productivity, delayed jobs, unhappy customers, and mounting costs.

When fleet managers talk about reducing downtime, they often focus on mechanical reliability and maintenance schedules. But there’s a hidden factor that plays a major role in fleet uptime: the vehicle fitout itself.

In this article, we explore the true cost of vehicle downtime—and why a well-designed fitout can be one of the smartest investments you make to keep your business moving.

The Visible and Hidden Costs of Downtime

It’s easy to calculate the obvious costs when a vehicle is out of action: missed jobs, rescheduled appointments, overtime to catch up, or hiring a replacement vehicle. But downtime has a ripple effect that goes far beyond those direct expenses.

Here’s what downtime really costs your business:

✅ Lost revenue from uncompleted work

✅ Damage to your reputation with customers who experience delays

✅ Additional admin costs to rearrange bookings or allocate alternative resources

✅ Employee downtime while waiting for a functional vehicle or tools

✅ Penalty fees or lost contracts for failing to meet service-level agreements (SLAs)

👉 Even a single van off the road for a few days can result in thousands of dollars in lost opportunity and extra expenses. Multiply that across a fleet, and the financial impact is significant.

Fitouts: The Unsung Hero in Uptime

While vehicle maintenance is critical to uptime, many businesses underestimate how much a poor or outdated fitout contributes to downtime.

Consider these common fitout-related causes of downtime:

🔧 Shelving or racking breaking under load, requiring repair before the vehicle is safe to use

🔧 Poor storage design leading to damaged tools or parts, delaying jobs while replacements are sourced

🔧 Non-compliant load restraint systems causing safety breaches or fines, taking vehicles off the road for rectification

🔧 Inefficient layouts that slow down technicians, increasing job times and reducing how many jobs can be completed each day

A fitout that isn’t designed for the demands of your work doesn’t just make things inconvenient—it actively increases the risk of downtime.

The Link Between Fitout Quality and Maintenance Costs

It’s easy to overlook the long-term impact of fitout materials and construction. Low-quality components may save you money upfront but lead to:

- Faster wear and tear under daily use

- Increased need for repairs or replacements

- Potential damage to the vehicle interior

- Higher total cost of ownership over the life of the vehicle

By contrast, a durable, professionally designed fitout can reduce:

✅ The likelihood of structural failures

✅ Vehicle interior damage

✅ Ongoing maintenance and repair interruptions

👉 Every extra day a vehicle needs fitout repairs is another day of lost productivity. Investing in quality from the start prevents these avoidable downtimes.

Fitout Design Directly Impacts Workflow Efficiency

Downtime doesn’t only mean the vehicle is off the road. If your fitout makes it harder for technicians to find tools, access parts, or work safely and comfortably, you’re creating micro-downtimes every single day.

For example:

❌ A technician spends 10 minutes searching for a part that could be at arm’s reach in a better layout

❌ They have to unpack other equipment to access a needed tool

❌ They make multiple trips back to the vehicle for items because of poor organisation

Multiply those inefficiencies across dozens of jobs per week, across a fleet of vehicles, and the hidden productivity loss adds up fast.

A well-thought-out fitout reduces these inefficiencies by:

✅ Providing logical, intuitive storage for faster access

✅ Securing all tools and parts to prevent shifting or damage in transit

✅ Minimising unnecessary movement for the technician

👉 Fitouts that improve workflow don’t just prevent breakdown-related downtime—they help technicians complete more jobs in less time every day.

Compliance Failures Can Take Vehicles Off the Road

Non-compliant fitouts can lead to serious legal and safety issues. In Australia, vehicles must meet load restraint guidelines and relevant occupational health and safety standards.

If a vehicle is stopped for a roadside inspection or involved in an incident and found to be non-compliant, it may:

⚠️ Receive a defect notice that removes it from service

⚠️ Incur fines or penalties

⚠️ Require immediate rectification before it can legally return to the road

That’s downtime you can’t afford—especially if it results in contractual breaches or liability exposure.

A reputable fitout partner will ensure your vehicles are designed and installed to meet Australian Standards, protecting your business from unexpected compliance-related downtime.

Downtime Affects More Than the Vehicle

It’s important to remember that downtime doesn’t just impact the vehicle—it impacts your people. When a technician doesn’t have a vehicle available or can’t access their tools effectively, it disrupts their schedule, increases frustration, and reduces job satisfaction.

In a competitive labour market, where retaining skilled workers is critical, ensuring your team has reliable, functional, and safe vehicles is part of building a positive work environment.

👉 An investment in better fitouts is an investment in your people’s ability to do their job well.

Fitouts as a Long-Term Productivity Strategy

When you add up all these factors, it’s clear:

✅ Fitouts influence vehicle reliability

✅ Fitouts influence job efficiency

✅ Fitouts influence safety and compliance

✅ Fitouts influence staff performance

Businesses that approach fitouts as a core part of their operational strategy—not just a checklist item—see better uptime, higher productivity, and lower total cost of ownership over the fleet’s lifecycle.

Invest Now to Reduce Downtime Later

The true cost of downtime is more than a lost day—it’s lost revenue, reputation, productivity, and staff morale. If you’ve experienced fitout-related disruptions or are operating with ageing, inefficient setups, it may be time to review your fleet’s fitout strategy.

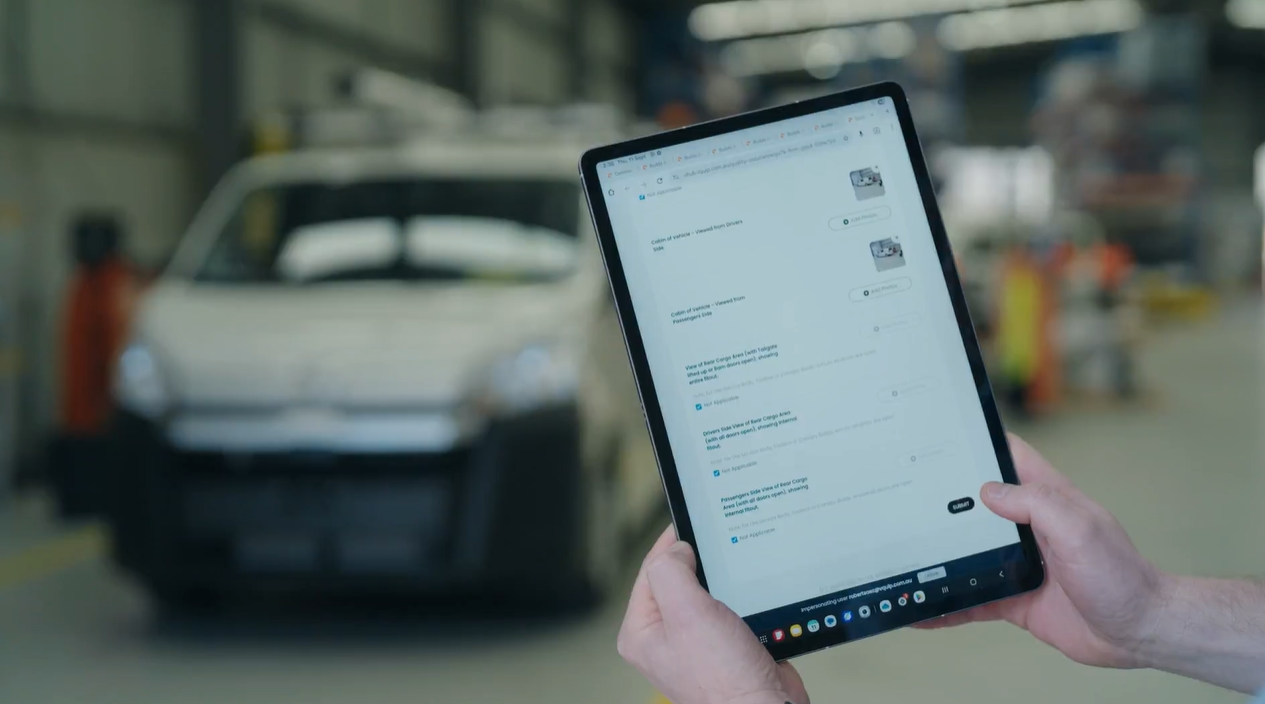

At VQuip, we design and install fitouts that help keep your vehicles on the road, your team working efficiently, and your business delivering for customers. Contact us today to discuss how we can reduce downtime through smarter, safer, and more durable vehicle fitouts.