Why Fitout Weight Matters in Electric Vans — And How VQuip Delivers a Solution

Jun 11, 2025

As businesses embrace electric vehicles (EVs) for their commercial fleets, a critical factor influencing performance, range, and compliance emerges: fitout weight.

While electric vans offer numerous benefits—lower emissions, reduced operating costs, and quieter operation—they also present unique challenges. One of the most significant is the sensitivity to additional weight, which can impact payload capacity and driving range.

Comparing Diesel and Electric Vans: The Weight Dynamics

To understand the implications of fitout weight, let’s compare two specific models:

2024 Renault Kangoo LWB Diesel:

-

Gross Vehicle Mass (GVM): 2,300 kg

-

Tare Weight: Approximately 1,544 kg

-

Payload Capacity: Approximately 756 kg

2024 Renault Kangoo E-Tech LWB Electric:

-

Gross Vehicle Mass (GVM): 2,490 kg

-

Tare Weight: Approximately 1,822 kg

-

Payload Capacity: Approximately 668 kg

Note: Figures are based on manufacturer specifications and may vary with different configurations and optional equipment.

The electric variant’s higher tare weight, primarily due to the battery system, results in a reduced payload capacity compared to its diesel counterpart. This difference underscores the importance of considering fitout weight in EVs.

The Impact of Additional Weight on EV Performance

In electric vans, every kilogram added affects:

-

Driving Range: Heavier vehicles consume more energy, reducing the distance achievable on a single charge.

-

Payload Efficiency: Increased fitout weight diminishes the available capacity for cargo and equipment.

-

Vehicle Wear: Additional weight accelerates wear on components like brakes and tires.

Therefore, optimising fitout weight is crucial to maximize the benefits of electric vans.

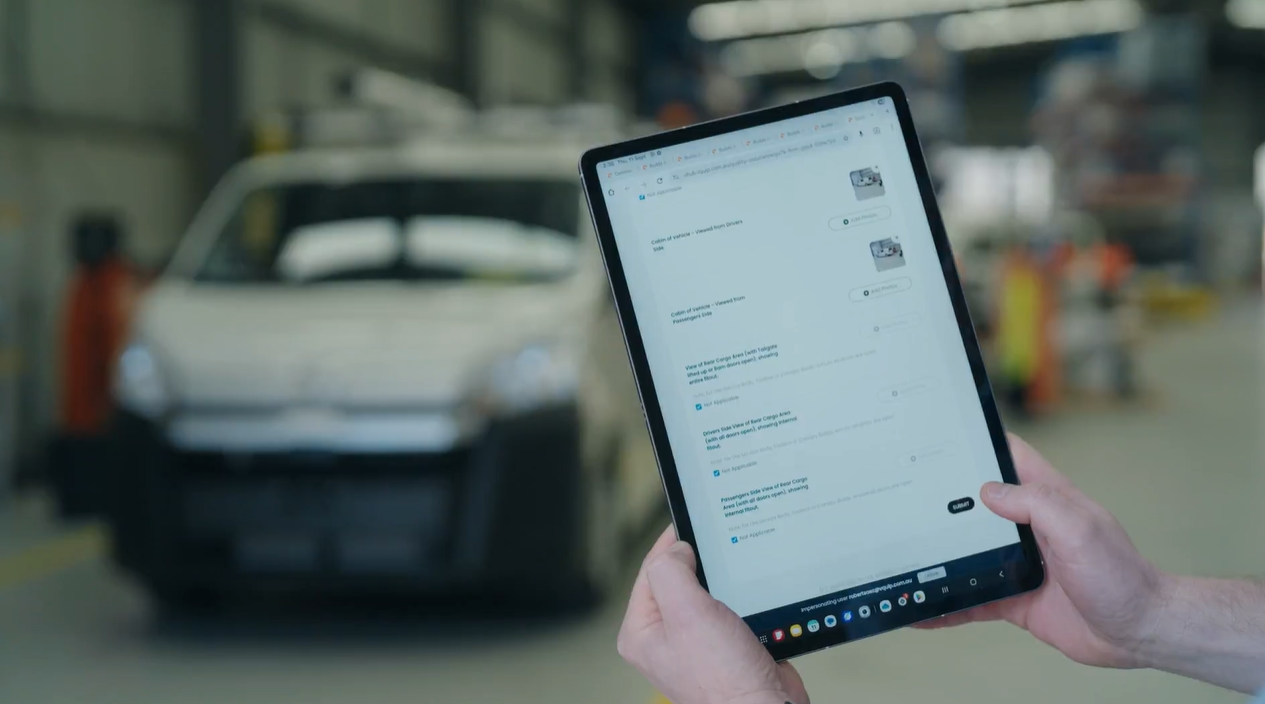

VQuip’s Lightweight Shelving Solution

At VQuip, we recognise the challenges posed by fitout weight in EVs. Our shelving systems are engineered to provide strength and durability without unnecessary weight:

-

Hybrid Construction: Combining steel end panels for structural integrity, aluminum extrusions for lightweight strength, and phenol formaldehyde resin-coated plywood shelves for durability.

-

Modular Design: Allows for customizable configurations to suit specific needs while minimising weight.

-

Corrosion Resistance: Materials selected to withstand harsh environments, extending the lifespan of the fitout.

This design approach ensures that your electric van maintains optimal payload capacity and driving range, without compromising on functionality or durability.

Benefits of VQuip’s Lightweight Fitouts for EVs

-

Enhanced Range: Reduced fitout weight contributes to longer driving distances between charges.

-

Increased Payload: More capacity available for tools, equipment, and cargo.

-

Lower Operating Costs: Improved energy efficiency leads to cost savings over time.

-

Compliance Assurance: Helps in adhering to legal weight limits, avoiding potential fines and penalties.

Conclusion

As the shift towards electric commercial vehicles accelerates, considering the weight of internal fitouts becomes increasingly important. VQuip’s innovative shelving systems offer a solution that aligns with the unique requirements of EVs, ensuring that businesses can fully leverage the advantages of electric mobility.

Ready to optimise your electric fleet? Contact VQuip today to learn how our lightweight shelving solutions can enhance your EV performance and efficiency.