Why Fleet Managers Should Spend a Day in the Technician Van

Feb 9, 2026

Fleet decisions are often made in meeting rooms, spreadsheets, and supplier presentations. On paper, a fitout can look efficient, compliant, and cost-effective.

But the real test of a fleet vehicle happens on the road and at the job site.

Spending a single day riding along in a technician’s van can reveal more about how a vehicle truly performs than weeks of documentation ever will. For fleet managers, it is one of the simplest and most valuable ways to make better fitout decisions.

The Van Is a Mobile Workplace

For technicians, the van is not just transport. It is a mobile workshop, storage facility, office, and sometimes even a break room.

Every task they perform flows through that space:

- Accessing tools and parts

- Loading and unloading equipment

- Completing paperwork or digital reporting

- Managing waste, spills, and clean-up

- Working around traffic, weather, and tight job sites

When a van is poorly laid out, every one of these tasks takes longer, requires more effort, and increases fatigue and risk.

What Looks Fine on Paper Often Fails in Practice

A layout that appears logical in a drawing can feel completely different in real use.

Common issues only obvious in real-world use include:

- Frequently used tools stored too high or too low

- Drawers that block access when open

- Components that require multiple steps to access

- Heavy items positioned in awkward lift zones

- Doors or partitions that restrict movement

These issues are rarely visible in CAD models or tender documents. They become obvious within minutes of working out of the van.

Small Inefficiencies Add Up Fast

A few extra seconds here and there does not sound like much. Across a day, it adds up.

Extra bending, stretching, or searching for tools slows technicians down and wears them out. Over months and years, this contributes to reduced productivity, higher injury risk, and frustration that impacts morale and retention.

From a fleet perspective, those small inefficiencies quietly turn into:

- Lost labour hours

- Increased WHS incidents

- Higher vehicle downtime

- Greater wear and tear on fitouts

Safety Risks Are Easier to Spot Inside the Van

Many safety risks are not obvious unless you are physically working in the space.

A ride-along highlights:

- Manual handling risks

- Slips, trips, and awkward movements

- Poor visibility or lighting

- Loose items that can become projectiles

- Access challenges when parked on uneven ground or in traffic

Seeing these risks firsthand makes it far easier to prioritise safety-focused design changes rather than treating WHS as a checklist item.

Technicians Adapt, Even When They Shouldn’t Have To

One of the biggest dangers is that technicians become very good at working around poor design.

They memorise where things are hard to reach. They accept awkward access as “normal”. They develop workarounds that hide deeper problems.

A fleet manager spending time in the van can see these adaptations in action and ask the right questions:

Why is that stored there?

Why does this take so long?

Why is this done in that order?

Those answers often reveal design issues worth fixing.

Better Decisions Start With Better Understanding

Fleet managers who spend time in technician vans make better decisions because they understand the consequences of those decisions.

They are better equipped to:

- Specify fitouts that support real workflows

- Challenge suppliers on practicality, not just price

- Balance standardisation with flexibility

- Justify design choices internally with confidence

It also builds trust. Technicians notice when fleet leaders take the time to understand their work environment.

Turning Insight Into Better Fitouts

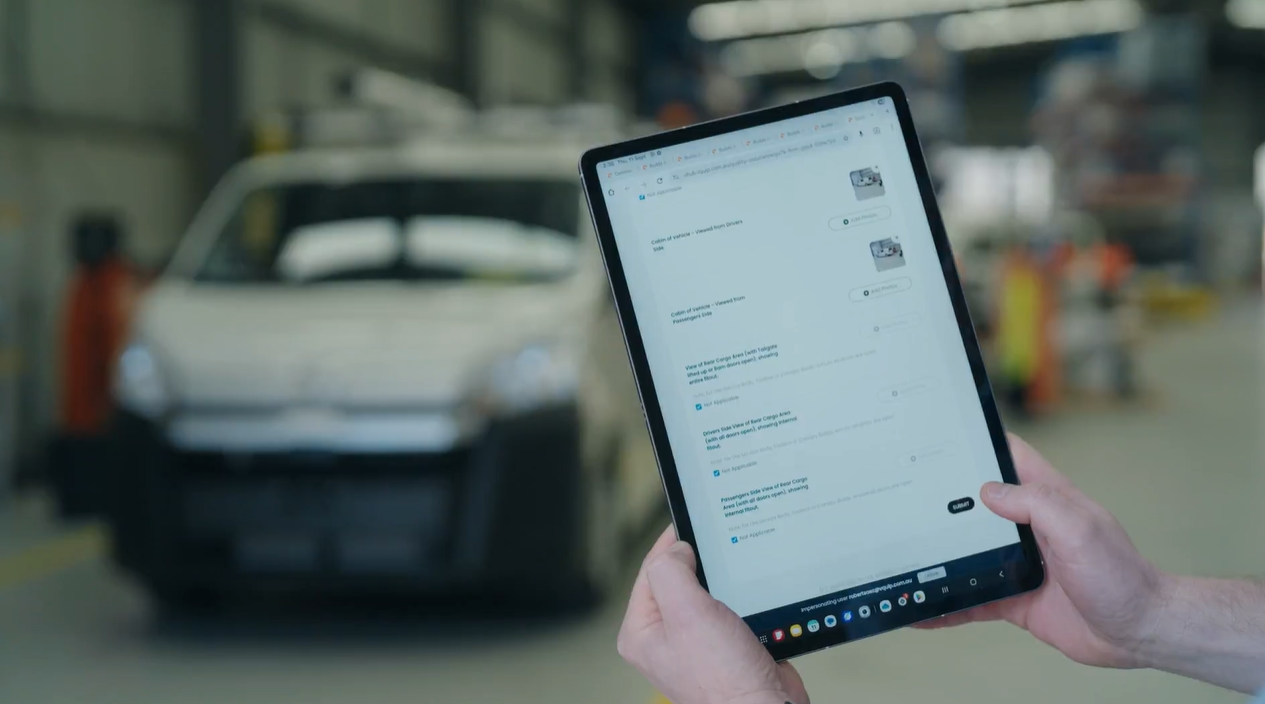

At VQuip, we strongly encourage fleet managers to engage with technicians early in the design process and, where possible, experience the vehicle as they do.

These insights directly influence:

- Layout and access decisions

- Storage types and placement

- Weight distribution and safety considerations

- Long-term durability and serviceability

When technician feedback is combined with engineering, compliance, and production expertise, the result is a fitout that works in the real world, not just on paper.

One Day, Long-Term Impact

Spending a day in a technician’s van does not slow a project down. It speeds everything up in the long run.

It reduces rework, improves safety outcomes, and leads to vehicles that genuinely support the people using them every day.

For fleet managers responsible for performance, safety, and cost over the life of a vehicle, there are few investments of time that deliver a better return.