Why Prototyping One Vehicle Can Save Hundreds of Thousands

Feb 9, 2026

When a fleet rollout involves dozens or even hundreds of vehicles, the temptation is to move fast. Lock in the design, finalise the quote, and get production underway.

But skipping a proper prototype build is one of the most expensive shortcuts a fleet can take.

A single prototype vehicle, built and reviewed properly, can prevent design errors, rework, downtime, safety issues, and inconsistent builds that quietly add up to hundreds of thousands of dollars across a national rollout.

Drawings and Renders Are Not Reality

Even the best CAD models and concept renders can only go so far. On screen, everything fits. In the real vehicle, things interact.

Shelving clashes with door operation. Access becomes awkward. Clearances disappear once wiring, batteries, or ducting are installed. Weight distribution shifts. Serviceability gets compromised.

These issues rarely show up until a vehicle is physically built. Finding them early, in one controlled prototype, is far cheaper than discovering them across an entire fleet already in service.

Small Design Issues Multiply Fast

A minor design oversight might seem trivial on a single vehicle. Across 100 vehicles, it becomes a serious cost.

Examples include:

- Needing to relocate components after installation

- Additional labour to rework access or mounting points

- Extra parts added late that were never in the original BOM

- Technicians losing time every day due to poor layout

- Increased WHS risk from awkward access or manual handling

Each issue on its own might only cost a few hundred or a few thousand dollars. Multiplied across a large rollout, the financial and operational impact can be massive.

Prototypes Protect Consistency

National fleets live or die by consistency. Every vehicle should work the same way, no matter which state it is built in or which technician is using it.

A prototype allows:

- Final confirmation of layout and access

- Validation of installation methods

- Locking down a complete and accurate BOM

- Ensuring weight and compliance requirements are met

- Aligning all teams on what “good” looks like before rollout

Without this step, small variations creep in between sites, suppliers, or build teams, leading to inconsistent outcomes and ongoing headaches for fleet managers.

BOM Accuracy Starts With a Physical Build

Bills of Materials are only as good as the process behind them. A prototype build forces every component to be accounted for.

It highlights:

- Missing fixings or brackets

- Incorrect quantities

- Components that looked good in theory but do not work in practice

- Opportunities to simplify or standardise parts

Getting the BOM right at the prototype stage protects pricing accuracy, purchasing efficiency, and production flow during the full rollout.

Operational Feedback Matters

A prototype also creates the opportunity to gather real feedback from the people who will actually use the vehicle.

Technicians can test access, workflow, and storage in a way no drawing ever allows. Adjustments made at this stage are inexpensive and straightforward. Making the same changes after rollout is disruptive and costly.

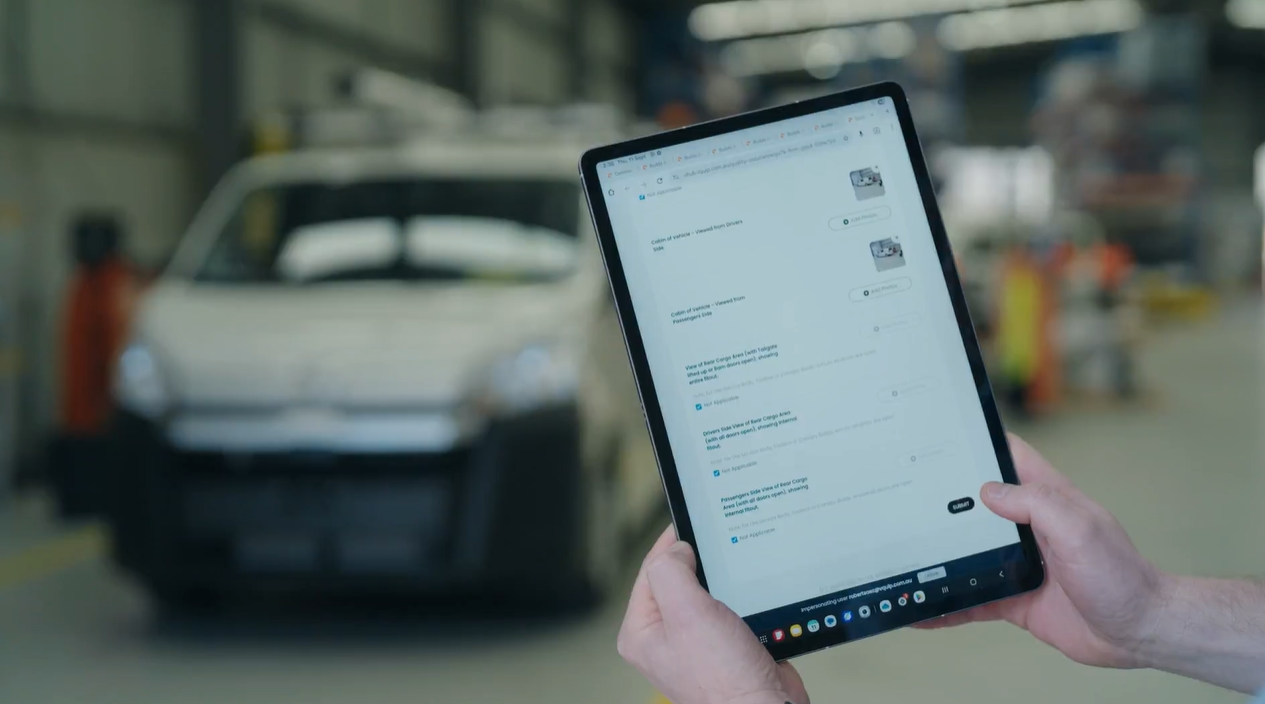

How VQuip Approaches Prototyping

At VQuip, we actively encourage a prototype build before any major national rollout.

We recommend that this prototype is built on-site at our Melbourne Head Office, where our design, engineering, and BOM management teams are based. This allows rapid collaboration between disciplines, immediate problem solving, and real-time design refinement as the vehicle comes together.

By having design, engineering, and production knowledge in the same place during the prototype phase, issues are identified early, resolved properly, and documented clearly before the rollout begins.

The result is a fitout that is proven, repeatable, and ready to be delivered consistently across multiple locations, without costly surprises.

The Smart Investment

Prototyping is not a delay. It is an insurance policy.

One well-executed prototype vehicle can protect budgets, improve safety, reduce downtime, and ensure your national fleet rollout performs as intended from day one.

When the stakes are high, the smartest fleets slow down once, so they do not have to fix problems hundreds of times later.