Dental Health Services Victoria (DHSV)

VQuip recently worked with Dental Health Services Victoria (DHSV) to develop a custom vehicle fitout for a fleet of Hyundai iLoad Crew Vans.

These vehicles supported a vital community program, enabling dentists to travel to schools and remote locations to provide on-site dental care.

The Original Challenge

DHSV initially went to open tender for the project. VQuip was not awarded the tender, but one concern stood out during the process: the proposed solution placed limited emphasis on end-user (dentist and driver) feedback.

Once the fleet began to be deployed by the successful tenderer, DHSV began receiving a high volume of complaints from users. Many of these were access and OH&S related, including difficulty safely reaching equipment, excessive manual handling, and inefficient setup and pack-down processes.

While the supplied fitout was modular and technically compliant, it was not designed around the real operational requirements of the dental teams using the vehicles every day.

In short, the vans were not fit for purpose.

When Modular Isn’t Enough

The key issue was not quality or intent, but design philosophy.

The original fitout relied heavily on modular components, with the expectation that users would adapt their work practices to suit the vehicle layout. In practice, this created:

- Inefficient workflows

- Excessive manual handling

- Difficult access to critical equipment

- Increased fatigue and safety concerns

This was a classic example of trying to make a square peg fit a round hole.

VQuip’s Approach: Start With the User

DHSV approached VQuip to help resolve the issue.

From the outset, the project had several tight constraints:

- A very limited budget

- A large volume of specialist equipment

- A compact vehicle platform

- Highly specific operational and clinical requirements

Rather than redesign in theory, VQuip asked DHSV to deliver a complete operational kit to our engineering centre. This included everything required for a full mobile dental setup, right down to the dentist’s chair.

Engineering Around Reality

Our team put the project through VQuip’s discovery, design, prototype and engineering process, focusing on:

- How equipment was accessed

- The sequence of on-site setup and pack-down

- Manual handling and OH&S risks

- Space constraints inside the iLoad Crew Van

A prototype solution was developed and refined in collaboration with DHSV before final sign-off

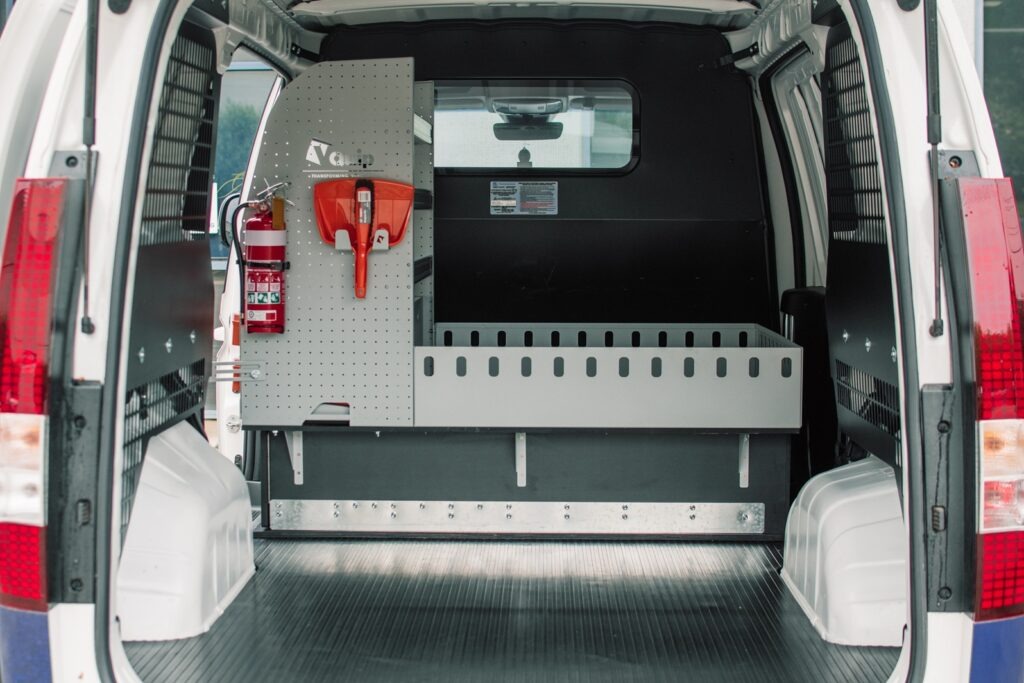

The outcome was a bespoke slide-out shelving system, engineered specifically around the full DHSV equipment kit and on-site workflows. The entire dental setup, including the dentist chair, could be accessed safely and efficiently without unnecessary lifting, reaching, or re-handling.

The Outcome

The redesigned fitout not only solved the original issues but exceeded expectations.

VQuip ultimately delivered 50+ new vehicle builds, including, retro-fitting 12 vehicles from the original tendered fleet that were already in service but failing to meet user needs.

Direct user feedback included:

“VQuip have made our jobs safer and easier. The constant communication, quick turnaround, and willingness to work with us has progressed UAT promptly without major delays.”

The Bigger Lesson

This project reinforces several important truths about fleet fitouts:

-

Operational feedback is critical. The people using the vehicle every day must shape the design.

-

Winning a tender on price does not guarantee value. A competitive material and fitment cost does not always translate to the lowest total cost of ownership.

-

Poor fitout design creates hidden costs, including inefficiency, fatigue, safety risk, and costly rework.

-

True partnership creates value that cannot always be written into the lines of a tender, but delivers real short- and long-term returns.

At VQuip, this experience continues to shape how we approach fleet fitouts today, designing solutions around how work is actually done, not just how components fit inside a vehicle.