From Concept to Cable: VQuip Rolls Out Splicing Vans for Service Stream

Service Stream required a fleet of specialised splicing vans to support their telecommunications operations. These vehicles are essential for cable splicing tasks in the field—particularly fibre optic splicing, where precision and reliability directly impact network performance.

Client Overview

Service Stream is a leading provider of end-to-end services in the design, construction, installation, operation, and maintenance of critical assets across Australia’s essential infrastructure networks. Their expertise spans telecommunications, utilities, transport, and other sectors where reliable service delivery is paramount.

Project Background

Service Stream required a fleet of specialised splicing vans to support their telecommunications operations. These vehicles are essential for cable splicing tasks in the field—particularly fibre optic splicing, where precision and reliability directly impact network performance.

What is Splicing?

Splicing involves joining two lengths of cable together so they function as a continuous run.

In telecommunications, this means:

-

- Fibre optic splicing: joining glass fibres with precision to maintain signal strength and quality.

- Copper cable splicing: joining wires by twisting, soldering, or crimping to maintain conductivity.

The splicing van therefore needed to be more than a transport vehicle—it had to function as a mobile workshop equipped for accuracy, safety, and efficiency in the field.

VQuip’s Approach

VQuip guided Service Stream through our proven end-to-end process, ensuring the fleet rollout was tailored to operational needs while being scalable for future requirements:

- Discovery Session – Collaborated closely with Service Stream to understand workflow requirements, splicing practices, and field challenges.

- Concept Render – Produced detailed visual concepts to demonstrate layout, accessibility, and compliance before fabrication.

- Prototype Build – Delivered and refined a working prototype, ensuring all design features met field use requirements prior to full rollout.

Fitout Inclusions

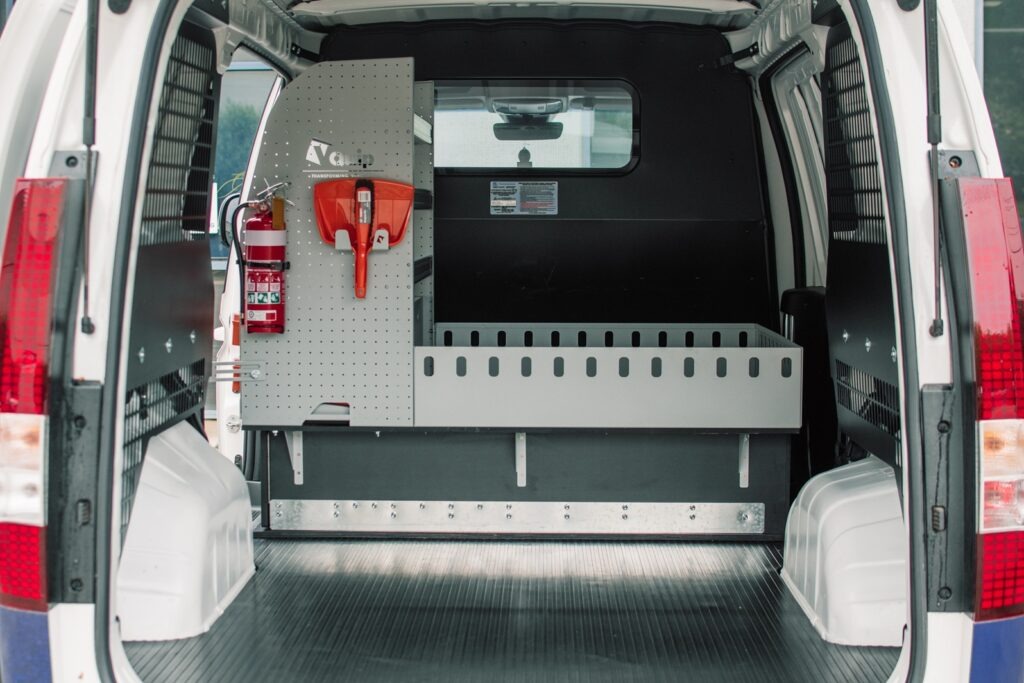

Each Service Stream splicing van was delivered with a purpose-built fitout, including:

- A custom-designed splicing hatch for safe and practical cable handling.

- Full shelving system with a dedicated splicing workbench, featuring an integrated vice slide and parts storage bins for optimal organisation.

- Roof rack system to expand equipment carrying capacity.

- A high-spec electrical fitout, including:

- Internal LED lighting and exterior worklights

- Dual battery system

- Power inverter for splicing equipment

- Rear step/towbar for safe access and towing requirements.

- Hardwood ply flooring for durability and easy cleaning.

- Protective wall linings to maintain the vehicle interior and improve safety.

Outcome

The completed rollout delivered Service Stream a fleet of fully operational, future-ready splicing vans. These vehicles now serve as mobile cable splicing workshops, enabling Service Stream’s technicians to complete critical fibre optic and copper cable work with efficiency, safety, and reliability across Australia’s infrastructure network.

By partnering with VQuip, Service Stream gained:

- A standardised fleet solution to support consistent workflows.

- Durable, high-quality fitouts designed for long-term performance.

- The flexibility to adapt for future rollouts with proven prototype validation.