Streamlining Electrolux’s Service Fleet for Greater Efficiency

Electrolux is a global leader in home appliances and air-conditioning systems, supplying innovative, high-quality products to homes and businesses across Australia. With a team of dedicated service technicians supporting both appliance and air-conditioning divisions, Electrolux needed a vehicle fitout solution that enhanced productivity, ensured compliance, and reflected their brand’s premium reputation.

Client Overview

Electrolux is a global leader in home appliances and air-conditioning systems, supplying innovative, high-quality products to homes and businesses across Australia. With a team of dedicated service technicians supporting both appliance and air-conditioning divisions, Electrolux needed a vehicle fitout solution that enhanced productivity, ensured compliance, and reflected their brand’s premium reputation.

Challenge

Electrolux’s service fleet plays a vital role in daily customer operations — each van operates as a mobile workshop carrying specialised tools, parts, and components. The challenge was to create two tailored fitout designs:

- One optimised for appliance service technicians

- One tailored for air-conditioning (HVAC) service technicians

Each required an organised, compliant workspace with secure storage, easy accessibility, and durable finishes suitable for demanding field use.

Our Approach

VQuip guided Electrolux through our proven sales and design process, ensuring every detail aligned with their operational needs and compliance requirements. This included:

- Discovery Meeting: Understanding how each technician interacts with their vehicle and identifying opportunities to improve efficiency and safety.

- Proposal Presentation: Developing detailed layout concepts for both technician roles, supported by Conceptual Renders and specification sheets.

- Finalisation & Implementation: Refining the chosen layouts and preparing for national rollout.

The Solution

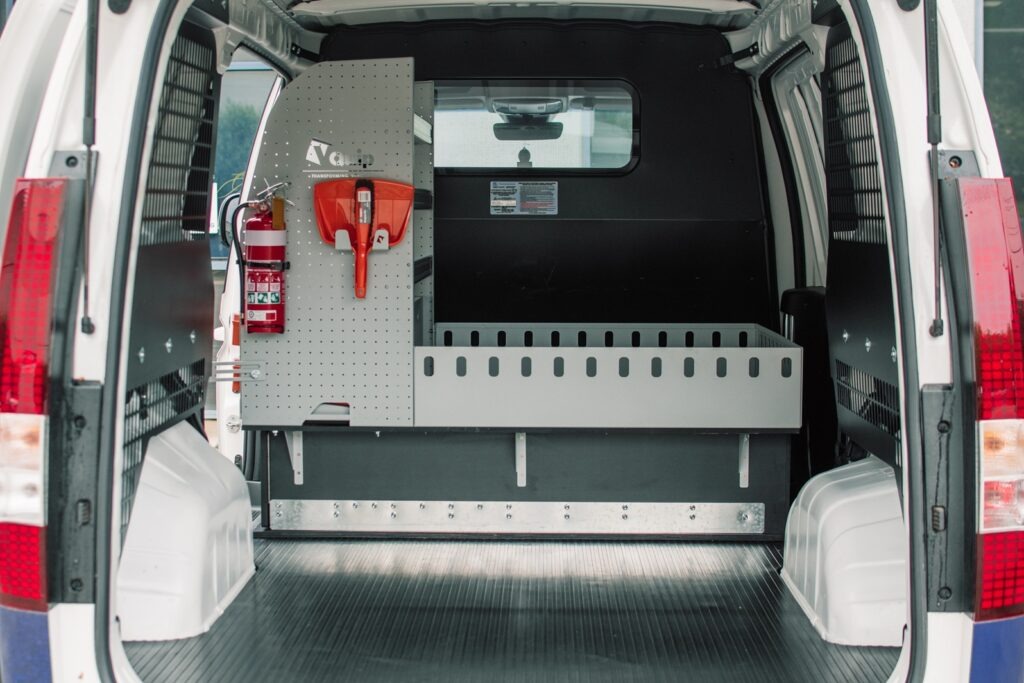

VQuip supplied and installed complete fitouts for the Toyota HiAce LWB fleet, using our Australian-made, crash-tested shelving system — engineered for safety and performance.

Each vehicle included:

- Crash-tested shelving with integrated parts bins for component storage

- Durable flooring system

- Crash-tested cargo barriers for driver protection

- Custom accessory selections

- Gas bottle storage and venting for HVAC vehicles

All shelving and fitout components are designed and manufactured in Australia, and tested to ADR crash standards for complete peace of mind.

Outcome

The final Electrolux fleet rollout delivered:

- Standardised layouts across vehicle types for brand consistency and technician familiarity

- Increased productivity through improved organisation and storage access

- Enhanced compliance and operator safety with ADR-compliant components

- A scalable fitout model that can be easily replicated for future vehicles across the country