The Evolution: How VQuip has helped Schindler Transition to Electric Vans

Schindler, a global leader in elevators, escalators, and moving walks, has a nationwide team of service technicians in Australia who rely on dependable vehicles as mobile workshops. With a growing commitment to sustainability, Schindler initiated a program to transition part of their fleet to electric vehicles (EVs), choosing the Volkswagen ID. Buzz Cargo as one of their first electric platforms.

Client Background

Schindler, a global leader in elevators, escalators, and moving walks, has a nationwide team of service technicians in Australia who rely on dependable vehicles as mobile workshops. With a growing commitment to sustainability, Schindler initiated a program to transition part of their fleet to electric vehicles (EVs), choosing the Volkswagen ID. Buzz Cargo as one of their first electric platforms.

The Challenge

Moving into EVs presented both opportunities and unique challenges:

- Weight & Compliance: Fitout weight directly impacts EV payload and range.

- New Vehicle Platform: With no established aftermarket fitout solutions available for the ID. Buzz Cargo, Schindler needed a bespoke solution.

- Technician Productivity: The fitout had to support daily service operations—secure tool storage, efficient access, and a safe working environment.

Schindler required a partner who could rapidly innovate, test, and deliver a compliant fitout for this new EV platform.

VQuip’s Solution

VQuip partnered with Schindler to develop a purpose-built EV fitout package, combining innovation with practical fleet support.

- 3D Vehicle Scanning: Using advanced scanning technology, VQuip captured the Buzz’s exact interior geometry, creating a digital foundation for design and testing.

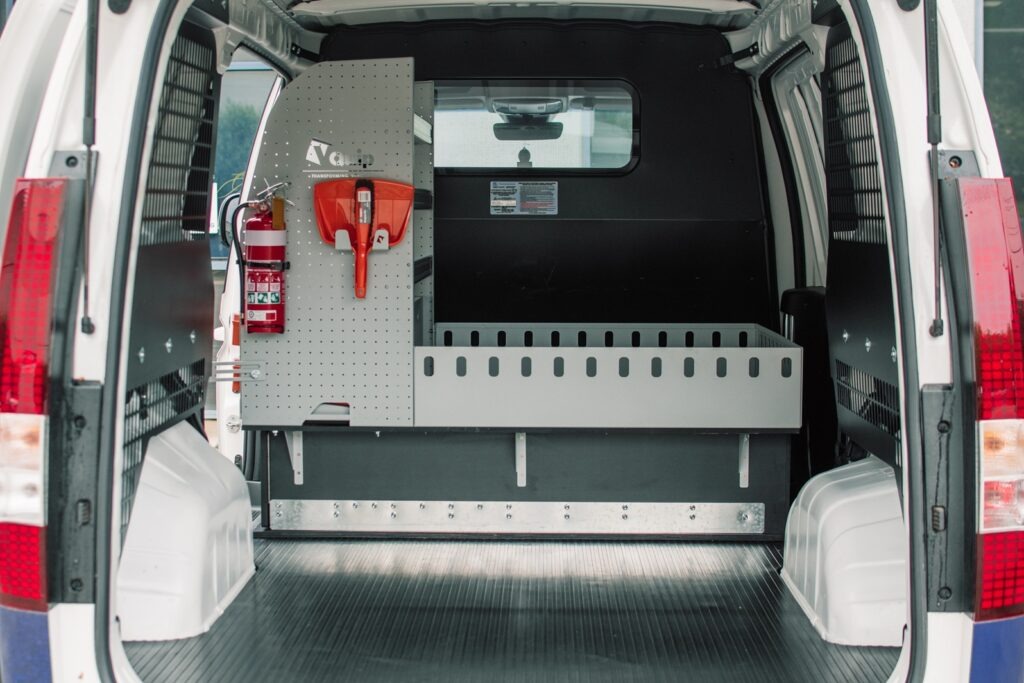

- Tailored Fitout Design: VQuip engineered and installed a package including a window, floor systems, shelving, and secure storage modules—optimised for weight and load balance.

- Future-Proofing: Designs were created with scalability in mind, ensuring this project could translate into wider EV fleet adoption.

About the Vehicle: Volkswagen ID. Buzz Cargo

- Load Volume: 3.9m³ (capable of carrying trade equipment and standard pallets)

- Battery & Range: 77kWh battery with up to 395km real-world range

- Fast Charging: 80% recharge in ~30 minutes (185kW charging)

- Access: Wide rear/side doors and underfloor storage compartments

The ID. Buzz Cargo provides flexibility for technician fleets but demands careful payload and weight distribution management—key factors addressed in VQuip’s design.

The Results

- Successful Delivery: Full fitouts were completed on Schindler’s EV vans, ready for deployment by their service technicians.

- Operational Efficiency: Secure tool storage, practical shelving, and floor protection improved technician workflow.

- Compliance & Safety: Fitout design maintained vehicle balance and ensured compliance with EV load restrictions.

- Scalable Framework: The project established a repeatable fitout model, paving the way for broader EV fleet adoption.

Client Impact

Schindler’s investment in EV fleet fitouts marks a significant milestone in their sustainability journey. By collaborating with VQuip, they not only gained a working EV fleet solution but also a future-ready fitout framework for electric commercial vehicles.

Looking Ahead

As more corporate fleets move toward electric platforms, VQuip continues to lead the way in EV-ready fitouts—balancing safety, compliance, and technician productivity with the unique requirements of next-generation vehicles.

Ready to plan your EV fleet fitouts?

Contact VQuip to start your transition today.